Custom Sofa Manufacturers in Atlanta turn raw lumber into showroom masterpieces. From Buckhead and East Paces Ferry to Roswell, Marietta, Alpharetta, and beyond, every step is yours—no off-the-rack shortcuts.

How Custom Sofa Manufacturers Reshape Living Spaces

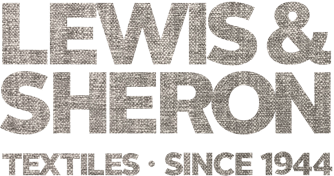

Step into our Buckhead studio and it feels like coffee with friends—your friends happen to be master craftsmen. We sketch, measure, riff on proportions. Then we dive into designer fabrics from Lee Industries, Verellen, Wesley Hall, and Ambella. Every swatch whispers quality.

Custom Sofa Advantages

- Personalized Dimensions that slide into odd nooks—from Collier Rd to West Paces Ferry—without leaving gaps.

- Premium Materials like kiln-dried hardwood frames and eco-certified textiles from Lewis and Sheron Textiles.

- White-Glove Delivery and setup across Buckhead, East Cobb, Cumming, Forsyth County, and beyond.

The bespoke sofa market is booming. Valued at USD 729.75 billion in 2025, custom segments grow at 6–9% CAGR. Bespoke sofas hit USD 35.47 billion in 2023, set to top USD 58.24 billion by 2031 as personalization outpaces mass churn. Discover more insights on Statista

70% of buyers in 2025 prefer green custom sofas—where craft meets sustainability.

You pick every detail—the swoop of the arm, the firmness of the cushion. It’s sofa couture, tailored to your story.

End-To-End Craftsmanship

- Frame assembly with precision joinery

- Suspension system installation using top-grade springs

- Layered foam cushioning tuned to your comfort profile

- Hand-stitched seams and a final quality inspection

This workflow slashes lead times by up to 40%—your custom sofa arrives in weeks, not months.

At Lewis and Sheron Textiles, we pair in-stock fabrics with made-to-order American upholstery. Reupholstery services, complimentary design consultations, and nationwide shipping keep Atlanta’s designers and homeowners covered.

Understanding Key Concepts Of Custom Sofa Manufacturing

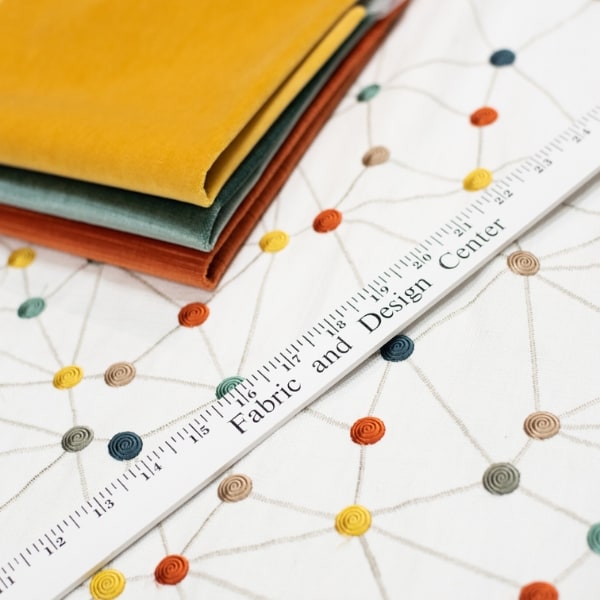

Building a custom sofa is like tailoring a Savile Row suit—it all starts with the frame. This backbone defines silhouette, strength, and longevity.

Frame materials typically split two ways. Kiln-dried hardwood delivers organic grain and durability. Engineered composites blend plywood and HDF for consistent strength and lighter weight.

Frame Construction Essentials

- Kiln-Dried Hardwood: prized for heirloom quality

- Engineered Composites: uniform, budget-friendly, easier to move

- Joinery Techniques: from classic mortise-and-tenon to cam-lock and dowels

“Kiln-dried hardwood frames stand the test of time in Atlanta living rooms,” says a Buckhead craftsman.

Next up: suspension. These hidden springs and webbing transform a rigid frame into a plush haven—your sofa’s tendons, essentially.

Suspension System Basics

- Coil Springs: gentle bounce and body-contouring support

- Webbing Straps: firm, even tension

- Hybrid Systems: the best of springs and webbing

Your suspension choice dictates years of comfort. Ask about spring gauge, webbing weave, and attachment methods.

Foam Density And Comfort

| Foam Density | Feel Description |

|---|---|

| 1.8–2.0 lb/ft³ | Plush, sink-in softness |

| 2.5–3.0 lb/ft³ | Medium-firm, everyday use |

| 4.0+ lb/ft³ | High-density, long-lasting |

Choosing foam is like picking a coffee roast—mellow give or bold support? Higher densities cost more but keep their shape.

Fabric Performance Metrics

A beautiful fabric must perform. Benchmarks include:

- Abrasion Rating (Double Rubs): 15,000+ for occasional use, 30,000+ for family rooms

- Eco Certifications: look for Oeko-Tex or GRS

Textiles from Ambella and Wesley Hall shine in these tests. Our designers in Roswell and Alpharetta put them through real-world trials—sunlight, spills, and all.

Global custom furniture hits USD 35.45 billion by 2025, surging to USD 65.67 billion by 2032 at a 9.2% CAGR. Sofas will account for 33.9% of that. Coherent Market Insights

Explore fabric selection tips in our guide on choosing the right fabric upholstery.

Comparing Custom Sofas With Ready Made Options

Choosing custom vs. ready-made is like a bespoke suit vs. off-the-rack tux. Only one bends to your room’s contours.

When you partner with a custom sofa manufacturer, you command every choice—from frame profile to stitch style. Local artisans in Buckhead, Milton, and North Georgia bring that vision to life.

Benefits Of Custom Sofas

- Personal Dimensions for odd corners or gallery walls

- Exclusive Fabrics from Verellen, Lee Industries, Ambella, Wesley Hall

- Custom Frame Strength and high-density cushions built for longevity

Trade-off: lead times of 8–16 weeks and an investment that reflects hands-on craftsmanship.

Benefits Of Ready Made Sofas

- Quick Delivery—sofas in days, not months

- Lower Entry Cost—though premium add-ons can climb

- Standard Sizes—fit conventional rooms but may leave gaps

Mass-market pieces favor speed and simplicity over personalization.

Custom Versus Ready Made Sofa Comparison

| Aspect | Custom Sofa | Ready Made Sofa |

|---|---|---|

| Dimensions | Precise fit for odd layouts | Standard sizes |

| Lead Time | 8–16 weeks | 1–4 weeks |

| Fabric Choices | 1000+ designer options | 10–50 selections |

| Cost | Higher investment reflects craftsmanship | Lower entry cost but add-ons can increase price |

| Fit Flexibility | Can fill odd corners or large walls | May not suit unusual room shapes |

Custom sofa manufacturers saw the market leap from USD 8.7 billion in 2024 to USD 9.3 billion in 2025, forecast to hit USD 14.1 billion by 2032 at 6.1% CAGR. North America led with USD 2.9 billion in 2024. CNC tech trims lead times by 40%, making bespoke more accessible. comprehensive bespoke furniture forecast

“30% of high-end US homes featured bespoke sofas in 2025,” says a design insider.

In Buckhead, East Cobb, Roswell, Alpharetta, and Marietta, custom pieces boost design impact and long-term value. Ready-made shines for quick turnovers in staged properties and apartments.

Ask about warranties, in-stock swatches at the Atlanta fabric showroom, and trade perks from Lewis and Sheron Textiles: volume discounts, design consultations, and white-glove delivery across North Georgia.

Tips For Decision Making

- Measure your space twice—odd angles count.

- Request actual swatches to test colors and textures in your light.

- Factor in shipping, installation, and warranty when you compare budgets.

Visit Lewis and Sheron’s Buckhead showroom to see both worlds and find the perfect fit.

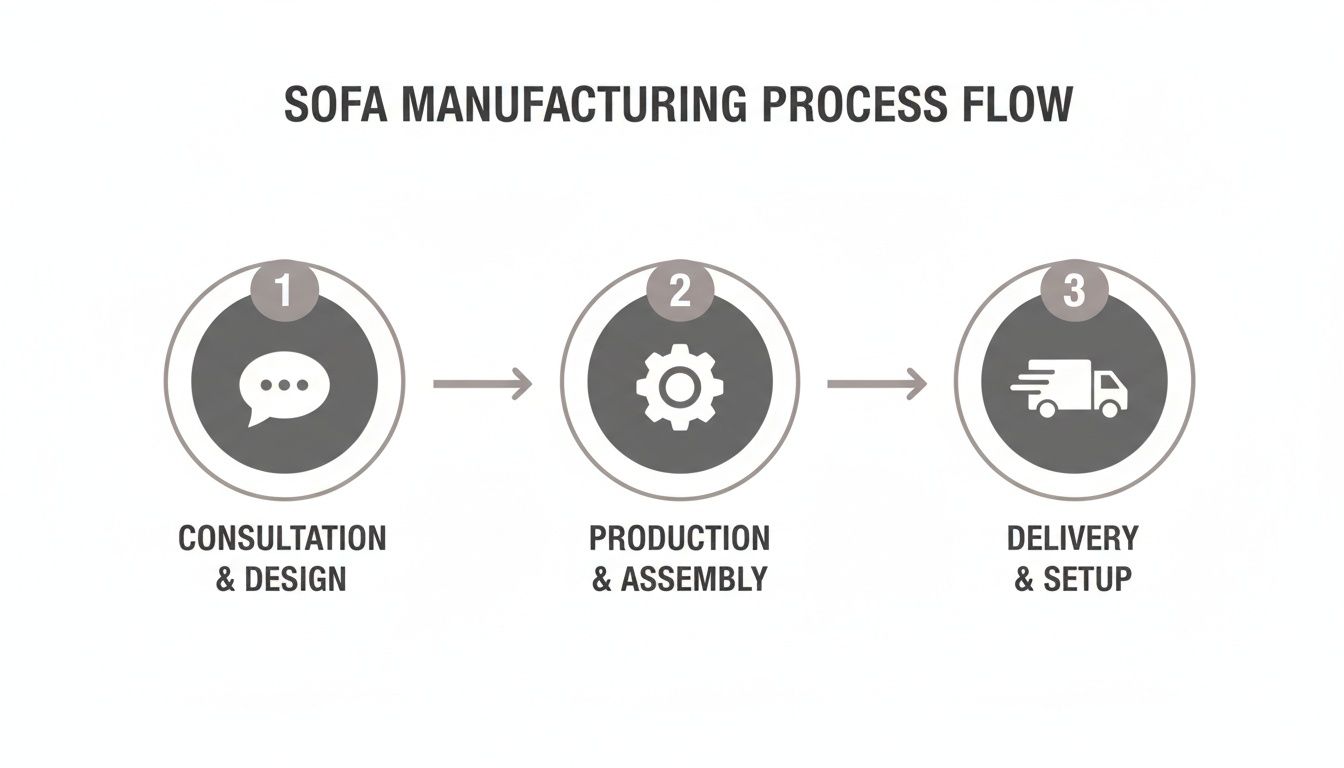

How Custom Sofa Manufacturing Works

Designing your sofa is like producing a film—each phase has its crew and purpose. From first sketch to final stitch, it’s craft and collaboration.

We kick off with a design consultation at our Buckhead studio. We measure, grab fabric swatches from Lee Industries and Ambella, and dive into your vision.

Then comes the 3D rendering—you click around, tweak proportions, and see how morning sun in Roswell spills across your sofa. That foresight cuts missteps by 30%.

“A solid consultation phase tackles errors early,” notes a senior designer.

Design Consultation And 3D Modeling

- Frame style, cushion comfort, fabric performance

- Exclusive textiles from Wesley Hall and Verellen

- Virtual lighting and scale checks for your Alpharetta living room

This rehearsal saves time—lead times fall by 40% overall.

Next, frame construction meets CNC precision.

CNC carving ensures joinery repeatable to fractions of an inch. We use FSC-certified, kiln-dried hardwood from North Georgia—local, low-emission, community-driven.

Frame Construction And Upholstery

- CNC carving and sanding for precise joinery

- Spring and support system installation for lasting comfort

- Foam layering tailored to your firmness preferences

- Hand-stitching and upholstery finishing for a flawless fit

We follow up with white-glove delivery across Roswell, Alpharetta, Milton, and beyond. Trade clients tap into the Lewis and Sheron Trade Program for volume perks. Homeowners get peace of mind with warranties on frames and seams.

Delivery And Quality Assurance

Your sofa arrives showroom-ready. Lead times stay tight, and footprints stay small.

Sustainable Practices And Local Partnerships

Every material reflects our commitment to planet and people. We source oak from Forsyth County sawmills that repurpose scraps. Partners like Lee Industries use low-VOC dyes and water-efficient processes.

- FSC-certified hardwood

- Water-based adhesives and finishes

- White-glove return service reclaims packaging

Choosing custom sofa manufacturers means investing in ethical craftsmanship that honors Atlanta’s tradition of quality and care.

Key Questions To Ask Manufacturers

Starting a custom sofa project? Arm yourself with these questions to spot top-tier makers:

- Lead Time & Warranty—safeguard schedule and investment

- Hardwood Source & Eco-Certified Fabrics—for quality and sustainability

- Cushion Fill Options & Durability Metrics—to match your lifestyle

- Shipping Logistics—white-glove delivery and installation

- Reupholstery Paths & Trade Program Perks—for long-term flexibility

Lead Time And Warranty

Turnaround is 8–16 weeks after deposit. If you need speed, ask about rush fees and guaranteed delivery slots in Buckhead or Roswell. Confirm warranty covers frames and seams, with some workshops offering a 10-year guarantee on hardwood.

Material Sourcing And Cushion Performance

Hardwood from North Georgia or FSC-certified mills? Eco-certified fabrics from Verellen, Wesley Hall, or Lee Industries? Cushion tech options:

- High-resilience foam for consistent support

- Feather-wrapped cores for plush sink-in feel

- Synthetic down alternatives for hypoallergenic comfort

“Aim for a double-rub count above 30,000 for daily-use upholstery,” advises an Atlanta designer.

Shipping Logistics And Trade Perks

White-glove delivery: handling fees, installation windows, suburban surcharges (Marietta, Alpharetta). Trade pros, join the Lewis and Sheron Trade Program for exclusive discounts and volume pricing. Factor in warehouse conditions—humidity and temperature matter.

Book styling sessions at Lewis and Sheron’s Buckhead Design Center. Compare quotes in a side-by-side matrix and choose with confidence.

For a deeper dive, check out 10 Questions to Ask When Choosing Upholstery with Lewis and Sheron.

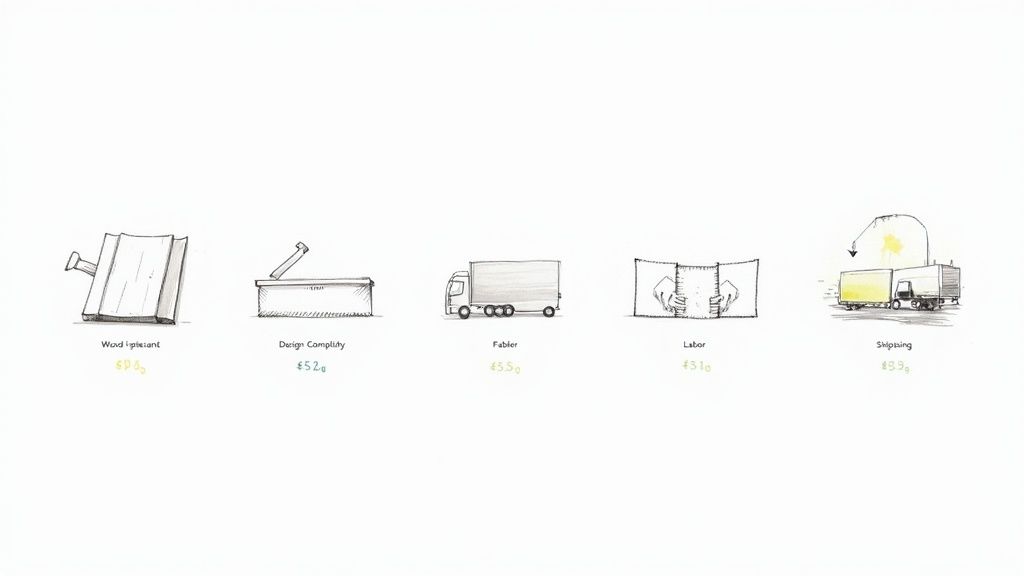

Cost Drivers And Sample Cost Breakdown

Decoding custom sofa pricing is like reading fine print on a couture price tag. Five factors move the needle: frame, design complexity, fabric, labor, and shipping.

Frame Materials Impact

- Kiln-Dried North Georgia Oak (2-seater): $800–$1,500

- Engineered Plywood: $500–$900

“Solid hardwood frames can boost lifespan by 30%,” says our lead craftsman.

Design Complexity And Labor

- Base Labor (frame, springs, foam): $600–$1,200

- Decorative Work (tufting, welting): $200–$600

- Rush Fee (<8 weeks): $350–$500

Fabric And Finishing Costs

- Performance Fabric: 15–18 yards; $900–$2,160

- Velvet/Linen (Verellen): 15–18 yards; $2,250–$5,400

- Leather (Ambella): 25–30 sq ft; $5,000–$13,500

Contrast piping or custom stitching: $150–$350 extra.

Shipping And Additional Fees

- Local white-glove delivery: $150–$300

- Suburban surcharge (Marietta, Alpharetta): $50

- Insurance: $75–$125

“Standard damage insurance is included,” confirms our logistics manager.

Typical Custom Sofa Cost Breakdown

| Cost Component | Typical Range | Notes |

|---|---|---|

| Frame | $500–$1,500 | Hardwood vs. composite |

| Labor | $600–$1,200 | Base assembly |

| Detail Work | $200–$600 | Tufting, welting, shaping |

| Fabric | $900–$13,500 | Varies by material |

| Delivery | $150–$350 | Local white-glove service |

| Rush Fees | $350–$500 | Optional for fast-tracked jobs |

| Insurance | $75–$125 | Transit damage coverage |

Use this table to plug in your specs. Refreshing an existing piece? Explore reupholstery cost insights here:

https://lsfabrics.com/blogs/the-stitch-and-scissor/how-much-does-reupholstery-cost

Tips For Working With Showrooms And Designers

A showroom visit is your deep dive into sofa craft—discover the story behind every frame and textile.

Booking a consultation at Lewis and Sheron’s Buckhead Design Center ensures an undivided, trade-savvy experience. Bring room measurements and inspiration photos. The team taps into 1,000+ in-stock swatches and hidden archive finds.

Plan Your Consultation

- Room Dimensions and Door Widths

- Activity Level: fabrics for kids, pets, and coffee spills

- Color Palette and Texture Preferences

Order And Test Swatches

- Request 6–8 labeled samples in zip-lock bags

- Photograph in natural light at home

- Compare on your sofa sketches to avoid returns

Coordinate Delivery And Installation

- Confirm build completion

- Provide 2–3 access dates for installers

- Note parking or elevator specs

“Early installation scheduling prevents 4-week delays,” advises a Buckhead design manager.

Maximize Trade Program Benefits

- 20% Off select Verellen furniture during design month

- Priority access to new Ambella collections

- Complimentary style consults for frames and fabrics

Bundle drapery and pillow services for a cohesive look.

Prepare Your Space

- Lay drop cloths to protect hardwood floors

- Clear entryways of obstacles

- Give a 48-hour heads-up on last-minute tweaks

With smart prep and clear communication, you’ll glide from showroom seat to living-room centerpiece. Trust Lewis and Sheron Textiles to introduce you to the best custom sofa manufacturers in Buckhead and North Georgia.

Visit Lewis and Sheron Textiles online: Lewis and Sheron Textiles