There's an art to crafting a window seat cushion. It's not just a sewing project. It's a dance of precise templating, cutting high-density foam just so, adding Dacron for that plush, professional finish, and sewing a custom cover with details like crisp piping or a hidden zipper.

It’s a project that marries precision with creative expression. And done right, it transforms a simple nook into the most coveted spot in the house.

The Art of the Designer Window Seat Cushion

A window seat is more than a place to sit; it’s a statement. It’s that perfect corner where the morning light hits just right, a quiet escape for reading, and a signature element in the sophisticated Atlanta homes we adore.

But what makes or breaks a window seat? The cushion.

A poorly made one screams amateur. A perfectly crafted cushion, however, elevates the entire room, turning that little corner into a luxurious retreat. This isn't about slapping some foam and fabric together. To get it right, you have to approach this with a designer's eye. Exploring the world of customized furniture can even spark incredible ideas for making your space feel truly unique.

Let’s walk through the process, from getting measurements perfect to finding exquisite textiles in our Buckhead showroom. You’ll learn the trade secrets to achieving the clean lines, lasting comfort, and bespoke look that defines high-end interiors—whether you're in Roswell, Marietta, or Forsyth County.

Elevating Your Space with Bespoke Comfort

This project is your chance to create something truly special. Think of it as a piece reflecting the quality you’d see in the finest high-end furniture Buckhead has to offer—the tailored perfection of a Wesley Hall sofa or the inviting comfort of a Lee Industries chair. That same level of detail is absolutely achievable.

This guide is for the discerning homeowner and our friends in the trade, sharing insights at the very heart of what we do at Lewis and Sheron.

A custom cushion isn't just an accessory; it's a piece of furniture. It must be beautiful, durable, and impeccably constructed to complement the luxury furniture and fine fabrics that define a well-appointed room.

It’s no surprise the global cushion market is projected to hit USD 23.94 billion by 2035. People are actively seeking quality. This demand is fueled by a desire for premium, sustainable materials, reflecting a broader shift toward thoughtful, lasting design—a philosophy we champion from our Atlanta showroom.

We’ll give you the knowledge to create a cushion that not only looks stunning but stands the test of time. Let's start crafting a piece worthy of your vision.

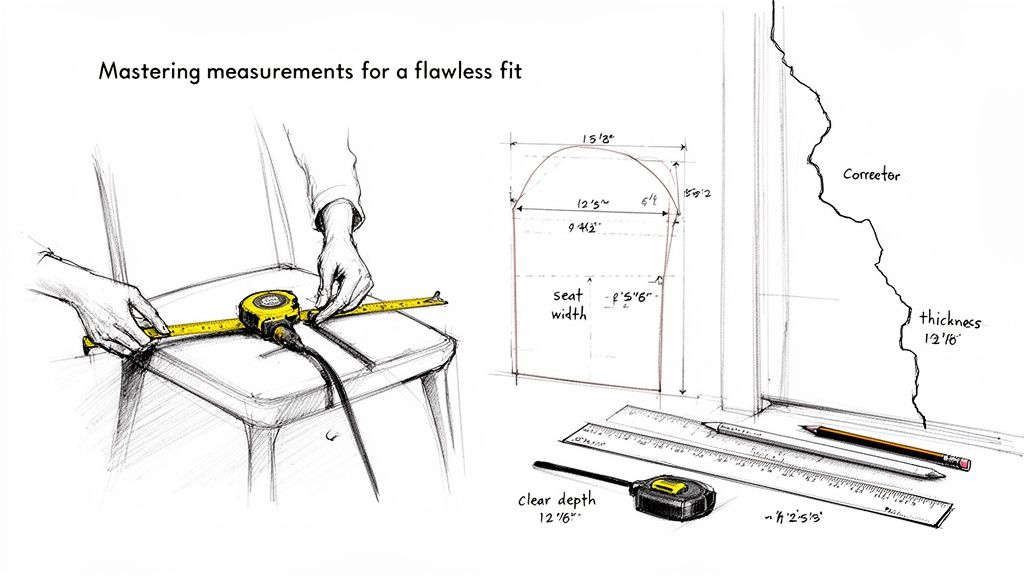

Mastering Measurements for a Flawless Fit

In high-end design, the little things are the big things. An ill-fitting cushion immediately signals amateur work, cheapening the entire look. So, let’s get this part perfect. The true foundation of a bespoke cushion isn’t the foam or even the gorgeous fabric—it's the template.

Especially in the charming, historic homes around Atlanta, from Buckhead to Milton, walls are rarely straight. That character is what we love, but it demands an exact template to avoid those tell-tale gaps. Forget guessing. We're creating a foolproof pattern that fits like a glove.

The Paper Template Technique

Grab a roll of brown craft paper. Lay it across your window seat, ensuring it covers the entire surface with a little extra.

Using a pencil, carefully trace the exact outline of the seat. Press the paper firmly into every corner and along every edge. This is crucial for capturing the subtle imperfections of the space. If you need to tape a few pieces together, do it. Don’t skimp here; a perfect template is your roadmap.

Once traced, cut it out. Place the paper template back onto the seat to double-check the fit. Does it lay flat? Does it meet every edge? If not, adjust now. This piece of paper is about to become the single source of truth for your foam and your designer fabrics.

Measuring for Success

With your template confirmed, grab a tape measure. Be meticulous. Document everything.

- Width: Measure the template at its absolute widest point. Take two more measurements at different spots. If the numbers vary, it just confirms your seat isn’t a perfect rectangle.

- Depth: Do the same for the depth, measuring from back to front at the center and near both ends.

- Label Everything: Write your final measurements directly on the paper template. Clearly note the "front edge" so there’s zero confusion later.

A common mistake is measuring the bench itself. Walls bow and angles are often off. Your template accounts for reality, not the architectural plan.

Determining Cushion Thickness

The final piece is deciding on thickness. This choice balances comfort and aesthetics.

- 3-Inch Foam: This offers a clean, firm, tailored look. It’s excellent for modern designs, providing solid comfort without overwhelming the space.

- 4- to 5-Inch Foam: This is where you get that plush, luxurious feel. It’s ideal for an inviting reading nook—the kind of look seen in high-end furniture from designers like Verellen or Wesley Hall.

Consider your seat’s height. A thick 5-inch cushion on an already tall bench might feel awkward. The goal is an intentional piece that feels designed with the furniture. This approach is what sets simple DIY apart from genuine custom upholstery work.

Choosing the Right Foundation in High-Density Foam

The soul of a luxurious window seat cushion lies beneath the surface. While beautiful designer fabric gets the attention, the unseen core—the foam—dictates comfort, longevity, and the crisp shape you see in high-end furniture all over Buckhead. It's the silent partner in your design.

Think of it like the foundation of a historic Atlanta home; without a solid base, everything else fails. Cheap, low-density foam sags and collapses, leaving you with a lumpy mess. High-density upholstery foam, however, is the professional standard. It’s the same quality inside a Wesley Hall sofa or a Lee Industries chair—engineered for years of resilience.

This is why it's worth a moment to understand foam. For a deep dive, understanding various foam properties and types like latex or memory foam can give you even more insight for making an informed choice.

Decoding Foam Density and Compression

Let's demystify the jargon. When you’re looking at foam, you'll see two key numbers:

- Density (pounds per cubic foot): This is about weight and durability, not firmness. A higher density number (2.5 lbs or more) means the foam is built to last. For a window seat that sees daily use, high-density is the only option.

- Compression or ILD (Indentation Load Deflection): This tells you how firm the foam feels. A higher ILD means a firmer cushion. For most seats, an ILD of 30-40 hits that sweet spot of solid support without feeling like a rock.

We see a growing appreciation for quality materials. In fact, the market for pressure-relief seat cushions is projected to hit USD 2.00 billion by 2036. This underscores what we know: people want construction that delivers superior comfort and lasting support, a principle we apply to every custom upholstery project.

Cutting and Shaping Foam Like a Pro

Once you have your high-quality foam, the next step is cutting it to match your template. Forget scissors; they’ll chew up the edge and leave a jagged, unprofessional mess.

The tool of the trade is a simple electric carving knife. Yes, the one from the kitchen. It slices through thick foam cleanly and precisely.

Lay your paper template on the foam and trace its outline with a marker. Holding the electric knife perfectly vertical, guide it slowly along your traced line. The goal is a crisp, clean 90-degree edge all around.

The Secret to a Plush, Crowned Finish

Here’s a trade secret that separates DIY from professional custom upholstery: wrapping the foam. This two-step process gives your cushion that plush, rounded "crown" and a perfectly full look.

First, wrap the foam in a single layer of Dacron batting. This polyester material smooths out sharp edges and helps the cushion slide into its cover easily. Pull it taut and use a bit of spray adhesive or a stapler to tack the seam together on the bottom.

Dacron is the magic ingredient. It adds that gentle, rounded contour that prevents your cover from looking flat and empty. A small step with a massive visual impact.

Next, for a more luxurious feel, add a layer of quilt batting over the Dacron. This adds extra volume and softness, ensuring your cushion has that high-end, inviting look. This layering technique is exactly what gives custom cushions on Verellen and Ambella furniture their signature plumpness. It’s this meticulous attention to the unseen layers that truly defines quality.

Selecting Exquisite Fabrics for Your Window Seat

This is where your window seat comes to life. While precise measurements and quality foam are the foundation, the fabric is the soul. It dictates the personality, feel, and durability of your bespoke cushion. At our Atlanta fabric showroom on Collier Rd, we help designers and homeowners find the one.

Forget just picking a pretty pattern. Think like a designer. The fabric you choose is an investment. It has to stand up to sunlight, cozy reading sessions, and years of admiration. This is your chance to select a textile that elevates your space, connecting with your existing luxury furniture in Buckhead.

Durability and Cleanability: A Designer’s Priority

Before you fall for a delicate silk, let’s talk reality. A window seat is often a high-traffic area. It’s also bathed in sunlight, which can be brutal on textiles.

Here’s what I tell my clients:

- The Double Rub Count: This is the industry standard for abrasion resistance. For a residential window seat, you want at least 15,000 double rubs. For heavy use, aim for 30,000 or more.

- Performance Fabrics: Textiles like Crypton are game-changers. Engineered for stain, moisture, and odor resistance, they offer peace of mind without sacrificing a luxurious hand-feel. They are the perfect marriage of practicality and beauty, ideal for homes in East Cobb or Alpharetta.

- Lightfastness: Check the fabric’s rating for resistance to fading. A higher grade means your beautiful colors will stay true, even in the sunniest spots.

Think of it like dressing your furniture. You wouldn't wear silk to go hiking, right? Same logic. For a deeper dive, our guide on how to choose upholstery fabric is an excellent resource.

Calculating Yardage Like a Seasoned Pro

Guessing your yardage is a costly mistake. Running out of a specific dye lot midway through a project is a designer's nightmare. Overbuying is wasteful. Let's get it right.

Calculating for a standard boxed cushion is straightforward. You need a top panel, a bottom panel, and side gusset strips. But luxury is in the details.

Piping is the tailored hem on a fine suit. It frames the cushion, defines its shape, and signals exceptional craftsmanship. Always account for extra yardage if you plan to include it.

A safe rule of thumb is to calculate the surface area of all pieces, then add at least 15-20% extra. This buffer accounts for seam allowances, bias strips for piping, and—most importantly—pattern matching. Large, bold patterns require significantly more fabric to ensure the design flows seamlessly.

Curating a Cohesive Look with Fine Fabrics

Now for the best part: choosing a textile that makes your heart sing. This is where you tie your new window seat into your home's design narrative. Imagine a fabric that picks up the texture of your Wesley Hall sofa or complements the lines of your Lee Industries chairs.

This is why designers across North Georgia, from Roswell to Cumming, rely on our Atlanta fabric showroom. They come for exclusive collections you won't find in typical retail stores.

Choosing the right high-end fabric can feel overwhelming, but breaking it down by material helps clarify the vision.

| Luxury Fabric Selection Guide | Best For | Considerations | Example Brands |

|---|---|---|---|

| Performance Linen | High-traffic areas, sunny nooks, homes with kids or pets. | Often a blend, so check the fiber content for the desired feel. | Libeco, Crypton |

| Cut Velvet | Creating a statement piece with rich texture and depth. | Can show wear patterns over time; best for less-frequented seats. | Kravet, Fabricut |

| Heavy-Duty Cotton/Linen | A timeless, versatile, and durable choice for any style. | Natural fibers can be more prone to staining if not treated. | P. Kaufmann |

| Bouclé or Chenille | Adding cozy, tactile comfort and a touch of modern luxury. | The looped texture can be snagged by pets. | High-end Mills |

Visiting our showroom lets you experience these textiles firsthand. Feel the weight of a Belgian linen, see the true color of a rich velvet, and coordinate it perfectly.

For our professional partners, the Lewis and Sheron trade furniture program provides unparalleled access to these collections, making it the ultimate Atlanta interior design resource for bringing exquisite visions to life. Your window seat cushion isn't just an addition; it's a chance to showcase your commitment to quality.

Constructing a Professional Boxed Cushion Cover

This is where the artistry happens. A flawlessly sewn boxed cushion, with its sharp corners and ruler-straight seams, is the biggest indicator of professional custom upholstery. It’s the detail that takes a project from “homemade” to something that looks right at home next to high-end furniture from Verellen or Ambella.

Let's walk through the process, but more importantly, let's understand the why behind each move. This isn't just following a recipe; it's about creating structure with fabric.

Precision Cutting Your Fabric Panels

A perfect cover starts with a perfect cut. Period.

Grab your paper template and sharp fabric shears. Lay your fabric completely flat, keeping the grainline straight to prevent weird pulling or warping.

You’ll cut three main pieces:

- The Top Panel: Trace your template onto the wrong side of the fabric. Add a ½-inch seam allowance around the entire shape.

- The Bottom Panel: An identical twin of your top panel.

- The Gusset (Side Strips): This long piece of fabric gives the cushion its depth. Measure the perimeter of your top panel, then cut a strip to that length plus a few extra inches. The width is your foam thickness plus a 1-inch seam allowance (½-inch for the top, ½-inch for the bottom).

So, for 4-inch thick foam, your gusset strip needs to be 5 inches wide. If your cushion's perimeter is 120 inches, cut a strip that's 5 inches by at least 122 inches. You may need to sew two shorter pieces together to get the full length—a standard pro move.

Installing a Hidden Zipper for a Flawless Finish

For a high-end cushion, a hidden zipper is non-negotiable. It makes the cover removable for cleaning, which is essential for longevity. It might look intimidating, but the logic is simple.

The zipper goes along the back edge of your gusset strip. You'll slice the gusset piece lengthwise, sew the zipper in place, then treat it like one solid piece again. The secret is using a zipper foot on your sewing machine; it lets you get a clean, tight stitch right up against the zipper teeth, making it disappear into the seam.

A well-installed zipper is a mark of quality. It speaks to thoughtful construction—a detail Atlanta interior design professionals always notice.

Creating and Attaching Custom Piping

Piping (or welting) gives your cushion that crisp, tailored edge. It transforms a simple fabric box into structured upholstery. You can buy it pre-made, but making your own from your chosen designer fabric ensures a perfect match.

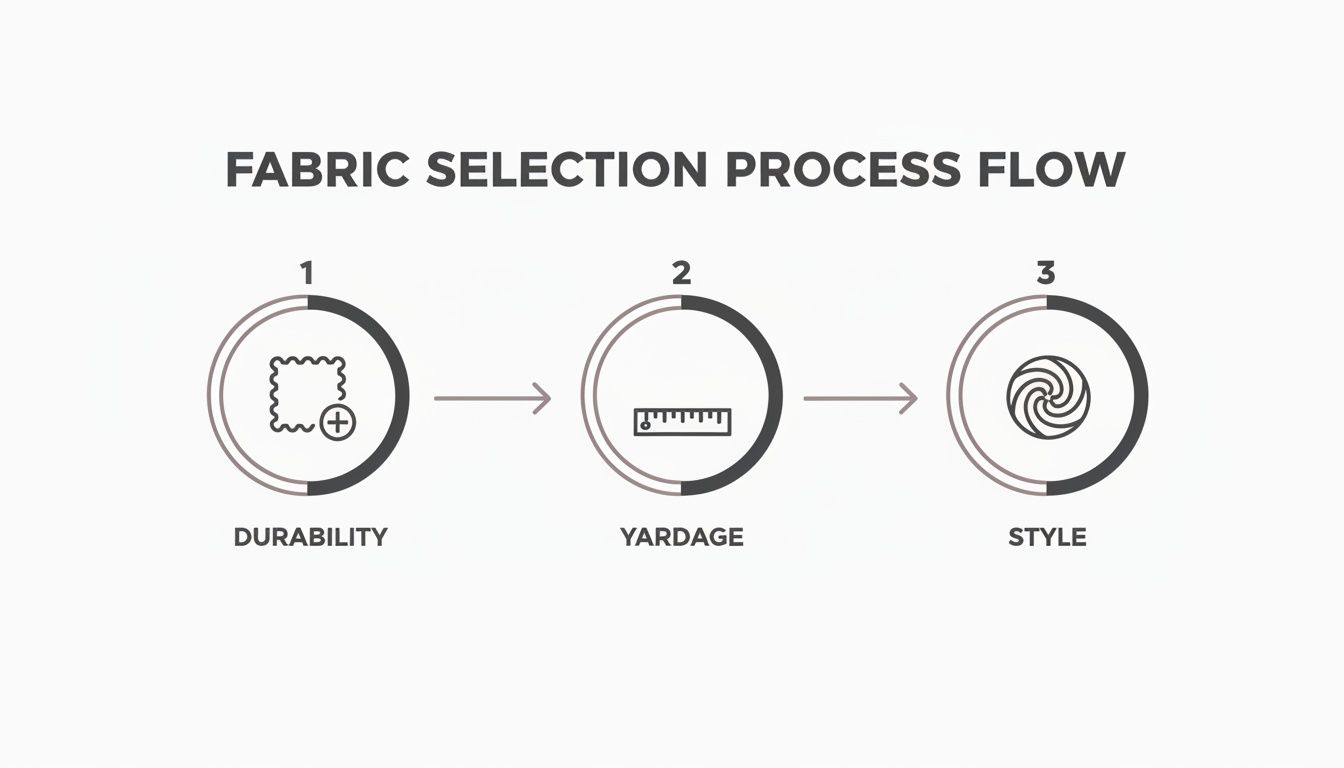

This visual guide shows the core steps for a successful fabric selection, ensuring durability, correct yardage, and cohesive style.

This process flow emphasizes that technical considerations like durability and yardage must be settled before finalizing the aesthetic style.

To make your own, cut long strips of fabric on the bias (at a 45-degree angle). This allows the fabric to bend beautifully around corners without puckering. You then fold these strips over cotton cording and stitch them closed with a zipper foot. For a deep dive, our guide on piping on cushions walks you through every step.

Once your piping is ready, baste it to the raw edges of your top and bottom panels. When you finally sew the gusset on, the piping gets sandwiched in the seam, creating that clean, professional line.

This meticulous approach separates the custom upholstery seen in fine homes from Milton to Marietta. It takes patience, but it results in a cushion that looks incredible and is built to last.

Deciding When to Call In the Experts

There’s a special pride that comes from a DIY project done right. But let’s be honest, there's a fine line between charmingly handmade and flawlessly professional.

So, when is it time to call in a master?

Some projects demand more than a can-do attitude; they require years of practiced skill. If your window seat has unusual curves or needs meticulous pattern matching for a large-scale print, the difficulty skyrockets. Getting a tricky fabric to flow seamlessly around corners is a true art form.

This is where Lewis and Sheron’s custom upholstery services shine. Our Atlanta-based artisans live and breathe this work, turning complex visions into stunning reality.

When Your Vision Demands Mastery

Certain design elements signal you might want a professional’s touch. If your heart is set on advanced techniques, trust the project to a seasoned hand.

Think about details like these:

- Intricate Button Tufting: Proper tufting isn’t just sewing on a button. It requires specialized tools and a deep understanding of tension to create those lasting dimples.

- Specialty Fabrics: Velvets and silks can be unforgiving. They require specific handling to prevent bruising, slipping, or puckering.

- Coordinating with Existing Pieces: Maybe your new cushion needs to perfectly complement the weave of a Verellen sofa or the texture of a Lee Industries chair. Our designers ensure a harmonious match.

This level of detail is why our trade furniture program is a vital resource for Atlanta’s interior design community. We work with designers from Roswell to Marietta, helping them execute their visions flawlessly.

The Value of Professional Craftsmanship

Ultimately, it comes down to the final result you want. A DIY cushion can be lovely, but a professionally crafted one is an investment in perfection and longevity. It's the difference between a cushion that fits the space and one that belongs in it.

Market trends show a clear preference for quality. The high-end cushion segment, featuring premium materials and expert construction, is seeing the fastest growth. It’s a signal that homeowners want superior comfort and durability. This shift highlights why discerning clients turn to specialists for guaranteed results. You can learn more about how consumers are prioritizing quality craftsmanship on datainsightsmarket.com.

Entrusting your project to our team means you're not just getting a cushion; you're commissioning a piece of bespoke furniture. We handle the complexities so you can enjoy the timeless design and impeccable finish.

From our Atlanta fabric showroom, we manage every detail, from creating a precise template to sewing the final stitch. For a closer look, explore our insights on local furniture reupholstery services. Choosing our experts guarantees a result that embodies the quality your beautiful home deserves.

A Few Common Questions We Get

Even the most straightforward design project can have its sticking points. Here are a few of the most common questions we hear from designers and homeowners who stop by our Buckhead showroom.

What Is the Best Foam Thickness for a Window Seat Cushion?

For most window seats, a foam thickness between 3 and 5 inches hits that sweet spot between comfort and a clean look.

A 3-inch foam offers a firmer, more tailored profile. But if you’re after that plush, luxurious feel—the kind you’d find in a high-end Wesley Hall or Verellen piece—a 4- or 5-inch foam delivers that inviting comfort.

Whatever thickness you choose, we always recommend high-density foam. It’s the key to making sure your cushion holds its shape for years.

How Do I Calculate Fabric Yardage for a Cushion with Piping?

First, measure the length, width, and depth of your cushion template. For a classic boxed cushion, you'll need two main panels plus the gusset strips for the sides.

Now, for the piping. A reliable rule of thumb is to add up the dimensions of your main pieces and then tack on an extra 1/2 to 1 yard of fabric. This buffer gives you enough material for the bias strips and any pattern matching you might need.

Of course, our experts in the Atlanta fabric showroom can give you a precise calculation based on your chosen fabric's width and pattern repeat.

Should I Pre-Wash My Upholstery Fabric?

As a general rule, we strongly advise against pre-washing high-end upholstery fabric.

Most fine textiles, especially natural fibers like linen or wool, can shrink, distort, or lose their specialized finish in a wash cycle. They are designed to be spot-cleaned or professionally cleaned only. Always check the manufacturer's cleaning code first.

This is especially true for performance fabrics like Crypton. Following their specific cleaning instructions is essential to maintaining the stain-resistant qualities you're paying for.

Ready to start your project with fabrics and furnishings that redefine luxury? Visit the Lewis and Sheron Textiles Design Center in Buckhead or explore our collections online.