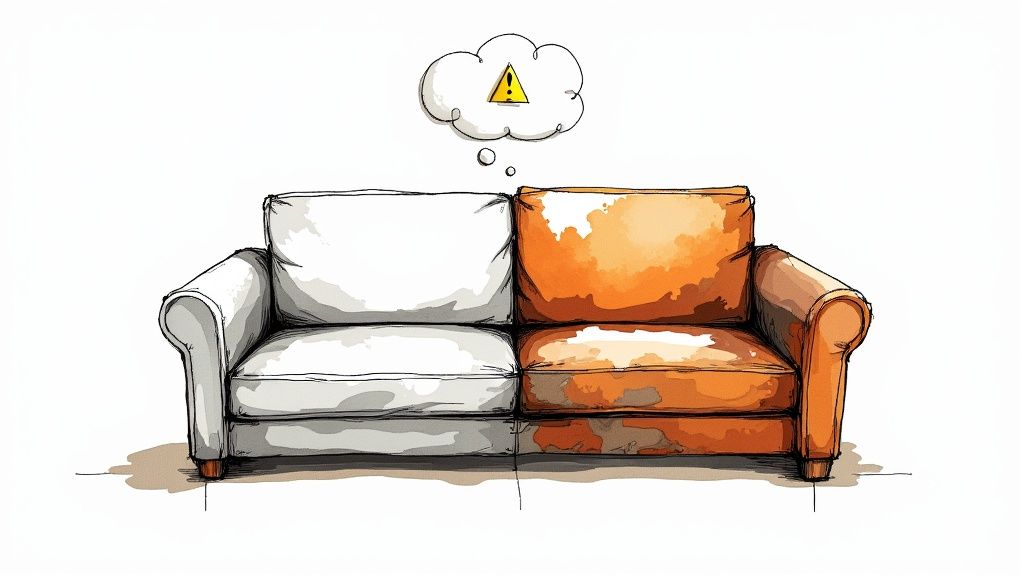

Dyeing furniture fabric is a bold move. Get it right, and you're a design genius. Get it wrong, and you’re left with a blotchy, irreversible mess that screams DIY-gone-wrong.

Success isn’t magic. It comes down to three things: the fabric's soul (its material), its current color, and any hidden treatments lurking within its fibers. This isn't just about slapping on a new color; it's a calculated project where knowing your stuff is everything.

The Dream and Danger of a DIY Color Transformation

We’ve all been there. You’re staring at that favorite sofa—the one with incredible bones but fabric that’s seen better days—and the thought hits: Can I just dye it? It’s a tempting idea, a dramatic refresh without the price tag of new luxury furniture in Atlanta.

But here’s the unvarnished truth: for every brilliant success story, there’s a cautionary tale of a faded, uneven catastrophe that looks far worse than where it started.

Step inside our Buckhead showroom, and you'll understand why Lewis and Sheron has been Atlanta’s destination for exquisite furniture and fine fabrics for decades. We’ve seen it all. We’ve advised homeowners from Marietta to Milton who are weighing this exact decision. It’s a project filled with incredible potential and significant risk, especially when you’re dealing with high-quality pieces.

Understanding the Stakes with High-End Furniture

When you're considering this for a designer piece—a classic Wesley Hall sofa or an elegant Lee Industries chair—the stakes are considerably higher. These aren't just pieces of furniture; they're investments. An amateur dye job can easily compromise the textile’s integrity and, frankly, diminish the piece's value.

This guide is your honest consultant. We’ll walk you through the critical first steps, helping you figure out which fabrics are prime candidates for a color revival and which are, well, destined for disaster.

The core truth is that dye is translucent. It adds to the existing color; it doesn't cover it up like paint. This is the single most important concept to grasp before you even think about buying a bottle of dye.

When to DIY vs. When to Call the Pros

We'll get into the realities of working with the kind of textiles you'd find on Verellen or Ambella furniture. These fabrics often have specialized weaves or factory-applied finishes that simply won't cooperate with DIY methods. It's crucial to know the limitations before you commit to a project that could go sideways fast.

This isn’t about discouraging your creative vision. It’s about channeling it correctly. You'll learn:

- Which fabrics are forgiving: Natural fibers like cotton and linen are your best friends here. They practically welcome a new hue.

- Which fabrics will fight you: Synthetics like 100% polyester often refuse to take dye evenly, if they take it at all.

- The hidden deal-breakers: Old stain-resistant coatings and subtle sun damage can completely sabotage your results.

Sometimes, the smartest design move is opting for professional custom upholstery. Instead of a risky color change, imagine your furniture reborn in an exquisite designer fabric from our Atlanta fabric showroom. For the interior designers we work with from Roswell to Alpharetta, our Lewis and Sheron Trade Program provides access to exclusive textiles that guarantee a flawless, lasting transformation. This guide will help you make that call with confidence.

Your Fabric's Hidden Secrets: A Critical Assessment

Before you even think about picking a dye color, you have to play detective with your fabric. This is the single most important step—the one that separates a design masterpiece from a blotchy tragedy. The success of any furniture dyeing project hangs entirely on understanding the material you're starting with.

Think of it like this: natural fibers are thirsty. Materials like cotton, linen, and silk drink up dye beautifully, giving you that rich, even color you're dreaming of. It’s why, when sourcing high-end furniture for our Atlanta clients, we often feature pieces from brands like Lee Industries or Wesley Hall, known for their stunning natural textile options.

Synthetics, on the other hand, are the opposite—they're hydrophobic. Engineered to repel water, they repel most common dyes by extension. Trying to dye polyester or nylon is like trying to stain a plastic water bottle. It's not impossible, but it demands harsh, specialized dyes, and the results are notoriously unpredictable.

Uncovering Fiber Identity and Invisible Roadblocks

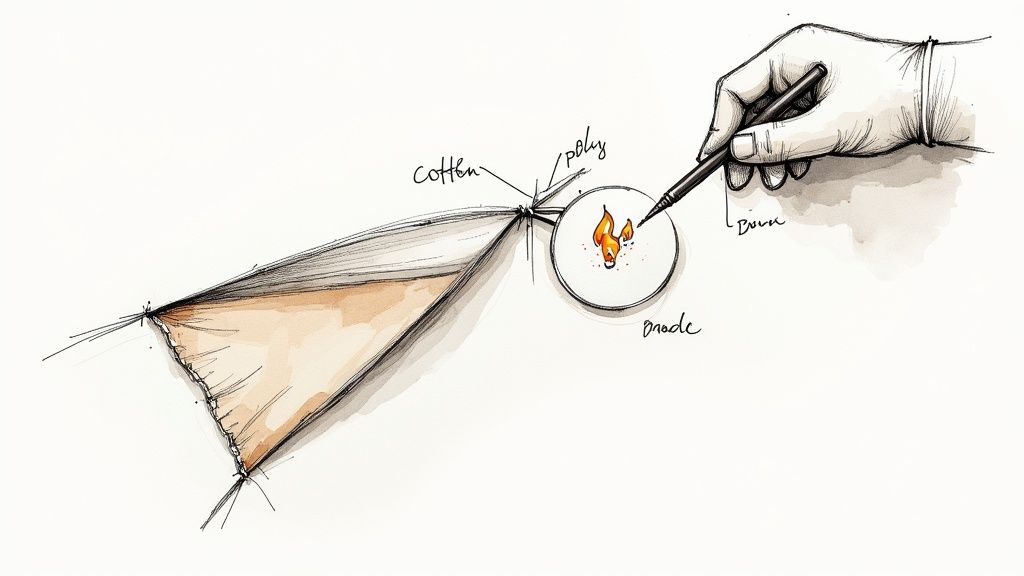

So, how do you figure out what you’re really dealing with? A simple burn test on a hidden swatch—a tiny snippet from under a cushion zipper—can reveal its identity. Natural fibers typically burn to a fine ash and smell like burning paper. Synthetics will melt into a hard, plastic-like bead.

But fiber content is only half the battle. You also have to scout for invisible roadblocks that will stop your dye dead in its tracks.

- Stain-Resistant Coatings: Many quality furniture fabrics come pre-treated. These chemical shields are fantastic for repelling spilled wine, but they’ll repel your dye just as effectively.

- Waterproofing Finishes: Similar to stain guards, these create an impenetrable barrier that prevents any moisture—including your dye solution—from soaking in.

- Sun Damage: A sofa that’s been basking in a sunny spot in a Buckhead or Roswell home might look fine at first glance. But UV rays break down fibers and alter their chemistry, causing dye to take unevenly. You’ll end up with a splotchy, faded look that only highlights the existing damage.

A flawless finish begins with knowing exactly what you’re working with. This isn’t just about color; it’s about chemistry. A deep understanding of fabric properties is fundamental, and you can start building that knowledge by exploring our guide on how to choose upholstery fabric.

Here's a quick cheat sheet to help you size up your fabric's potential.

Fabric Dyeability Cheat Sheet

| Fiber Type | Dyeing Potential | Key Considerations |

|---|---|---|

| Natural (Cotton, Linen, Rayon) | Excellent | These fibers absorb dye evenly and produce vibrant, rich colors. Best choice for beginners. |

| Protein (Silk, Wool) | Good | Dyeable, but require acid dyes and careful temperature control to avoid shrinking or damage. |

| Synthetics (Polyester, Nylon) | Poor to Difficult | Repel water-based dyes. Require special synthetic dyes (like disperse dyes) and high heat. Results can be unpredictable. |

| Blends (e.g., Cotton/Poly) | Variable | The fabric will only dye to the percentage of natural fiber. A 50/50 blend will result in a much lighter, heathered look. |

| Acrylic, Olefin | Very Poor | Generally considered undyeable in a home setting. These plastics won't accept color. |

Ultimately, natural fibers are your best bet for a successful DIY project, while synthetics are best left to the professionals.

The Bigger Picture: Fabric Finishing

When you assess your fabric, you're tapping into a much larger story. Fabric dyeing and finishing is a massive global industry. By 2024, this sector was valued at about $4.2 billion, employing roughly 18,000 people who specialize in achieving perfect color consistency and performance finishes.

This context is important. Your sofa's fabric has likely been through a highly sophisticated manufacturing process to make it look and perform a certain way—a process a home dye job can easily disrupt.

Before you jump in, it's critical to visualize how the new color will fit into your home's overall design. You can find fantastic inspiration by looking through interior design mood board examples to plan your new palette. This assessment phase is all about making sure your vision aligns with what's actually possible.

Choosing the Right Dye and Application Method

Once you've confirmed your fabric is a prime candidate, the next step is picking your tools. This isn’t like grabbing a can of paint at the local hardware store. Your choice of dye dictates the entire process, the final texture, and whether you end up with a masterpiece or a cautionary tale.

Not all fabric dyes are created equal, and using the wrong type is a fast track to regret. The chemistry has to be right. It's the practical science that separates a successful DIY from a serious mess.

The Three Main Contenders

Your options generally fall into three categories, each with its own personality and best-use case.

- Liquid Dyes: The most user-friendly option. They come pre-dissolved, making them great for beginners who want an even mix. They're wonderfully versatile for direct application with a brush or sponge.

- Powder Dyes: Potent and cost-effective, especially for big jobs like a sectional's cushion covers. With powder, you have absolute control over concentration for deep, rich colors. The catch? They must be fully dissolved in hot water to avoid a speckled, uneven finish.

- Upholstery Sprays: Think of these as a hybrid between dye and paint. They're incredibly convenient for a quick color refresh but can alter the fabric's texture, sometimes leaving it a bit stiff. Best for simple, flat surfaces, less ideal for plush fabrics like chenille or velvet.

The global textile dyes market, which directly impacts the products you see on the shelf, was valued at approximately USD 11.3 billion in 2024. This massive industry ensures a continuous supply of diverse dye products, driven by both commercial and home use. You can get more insights into the textile dyes market on imarcgroup.com.

Chemistry is King: Fiber-Specific Dyes

Beyond the format, the chemical makeup of the dye is absolutely critical. Matching the dye to your fabric's fiber content is non-negotiable.

- For Plant-Based Fibers (Cotton, Linen, Rayon): Go for a fiber-reactive dye. These dyes form a permanent covalent bond, resulting in vibrant, wash-fast colors that won't bleed or fade. This is the gold standard.

- For Protein-Based Fibers (Silk, Wool): You’ll need an acid dye. Don’t let the name scare you; it simply refers to the mild acid (like white vinegar) you'll add to the dyebath to help the color permanently bond.

- For Synthetics (Polyester, Nylon): This is where things get tricky. These are essentially plastics and require special disperse dyes and very high heat. It's a process very difficult to achieve safely and effectively at home.

Choosing the right dye isn't a suggestion; it's the fundamental rule of the game. A fiber-reactive dye on a polyester cushion will simply wash right off, leaving you with a watery, disappointing mess.

Application Method: Immersion vs. In-Place

How your furniture is built dictates how you'll apply the dye. There are really only two paths here.

An immersion bath—submerging the fabric in a large container of dye—is the hands-down best way to achieve a perfectly even, saturated color. But this method is only possible for removable slipcovers or cushion covers. You simply cannot submerge an entire sofa.

For a fully upholstered piece, like a Wesley Hall sofa from a high-end furniture store in Buckhead, a direct, in-place application is your only option. This involves meticulously applying the dye with brushes or sponges right onto the furniture. It demands incredible patience to avoid drips, streaks, and a splotchy finish. Honestly, this is where most DIY projects go wrong, which is why professional custom upholstery is often the wiser investment.

Achieving a Flawless and Even Application

Alright, this is where the real work begins. You've assessed your fabric and picked your dye—now it’s all about execution. The difference between a designer-level finish and a blotchy mess comes down to patience and precision.

First things first: your prep work is non-negotiable. A deep, thorough cleaning is your most critical task. Hidden oils, dust, or old cleaning products will act as a dye repellent, guaranteeing an uneven result. Meticulous preparation is everything, much like knowing how to prep cabinets for painting for a perfect finish. It's the unglamorous work that makes all the difference.

The Art of Layering and Saturation

Forget trying to get the perfect color in one go. The secret to rich, even saturation is building the color in thin, deliberate layers. Think watercolor painting, not slathering on house paint. A single, heavy coat will only lead to drips, runs, and dark patches.

This layering method gives you total control over the depth of the shade and allows you to correct inconsistencies as you go. It’s a process that demands a steady hand, a must for achieving a professional look with your project.

This process flow helps visualize the core decisions in dyeing furniture fabric.

As you can see, your fabric type, chosen tool, and application method are all interconnected decisions that ultimately shape the final result.

Once your layers are built up, it’s time to make it permanent. Heat-setting is the crucial final step that locks the dye into the fibers. Every dye has its own instructions for this—some require a hot iron (with a press cloth), others a trip through the dryer. Skipping this step guarantees the color will rub off on clothes, a frustrating problem known as crocking.

Remember, the goal is to work the dye into the fibers, not just paint it on top. For plush fabrics, use a sponge or soft-bristled brush to gently work the color into the weave from multiple directions, ensuring no spot is missed.

Creating Your Perfect Custom Shade

Store-bought colors are a fantastic starting point, but true design mastery comes from creating a shade that’s uniquely yours. Don't be afraid to mix dyes—just stick with the same brand and type.

For custom color mixing, keep these tips in mind:

- Start Small: Always mix a small test batch first. Use measuring spoons to keep track of your ratios (e.g., 3 parts navy to 1 part black).

- Test on a Hidden Spot: Apply your test batch to an inconspicuous area, like the underside of a cushion.

- Let It Dry Completely: Dye always looks darker when wet. You have to let your test swatch dry completely to see the true final color. It’s a lesson in patience we preach to designers from Alpharetta to Forsyth County.

This careful, methodical approach is what separates an amateur attempt from an exquisite transformation. It’s challenging, and if the risks of a DIY job on a valuable piece like a Verellen sofa seem too high, it might be time to consider another path. Our guide on how to reupholster furniture offers an alternative that guarantees a perfect, professional finish every time.

Knowing When to Call In the Pros

Let's be honest: sometimes the smartest DIY decision is knowing when not to do it yourself. Dyeing furniture fabric is a high-stakes game, especially with a valuable piece. Knowing when to step back is the mark of a true design connoisseur.

If the fabric is a delicate silk, a tricky synthetic, or a priceless vintage textile, the risk of irreversible damage is just too high. The same goes for high-end designer furniture from brands like Verellen or Ambella. A DIY dye job can seriously diminish its value. These are investment pieces, built with specific textiles chosen for their unique texture and beauty.

The Superiority of Custom Upholstery

This is where professional custom upholstery doesn't just offer a solution—it opens up a universe of design possibilities. Instead of a risky color experiment, imagine your furniture completely reborn in a stunning designer fabric from our Atlanta showroom.

When you choose professional upholstery, you’re getting:

- Perfect, Lasting Results: Master upholsterers deliver flawless tailoring. Every seam and welt is executed to perfection.

- Unmatched Durability: We use commercial-grade techniques and materials that ensure your furniture looks beautiful for years to come.

- Access to Exquisite Textiles: Our showroom on Collier Rd is a treasure trove for interior designers and homeowners from East Cobb to Forsyth County. You'll find an unparalleled selection of fine fabrics Alpharetta and Roswell residents prize.

Think of it this way: a DIY dye job is an attempt to alter what’s already there. Custom upholstery is an opportunity to completely redefine the piece with fabrics from world-class mills, turning it into a true custom creation.

A Resource for Atlanta's Design Community

For interior designers across North Georgia, our Lewis and Sheron Trade Program is the ultimate resource for transforming client pieces with genuine craftsmanship. It’s about elevating a vision beyond the limits of a DIY project. Why risk an unpredictable outcome on a Wesley Hall sofa when you can select an exclusive textile that enhances its form and presence?

This choice also aligns with responsible design. The sustainable textile dyeing market was valued at USD 11.91 billion in 2023 and is projected to grow significantly. This reflects a shift toward environmentally conscious methods. Professional upholstery allows you to select fabrics from mills leading this charge. Learn more in this sustainable textile market report.

Ultimately, the cost of a dyeing mistake often outweighs the expense of doing it right from the start. If you're wondering about the investment, we've broken it down in our guide that explores how much reupholstery costs. When in doubt, choosing expert craftsmanship is always the most timeless design choice.

Your Top Questions About Dyeing Furniture Fabric

We hear these questions all the time in our Atlanta showroom. Once a client starts thinking about dyeing their furniture, a host of concerns pop up. A little expert insight can make all the difference. Here are the answers to the questions we field most often from designers and homeowners.

Can I Dye a Patterned Fabric a Solid Color?

This is the big one. The honest answer is no, not if you want a clean result.

Dye is translucent—it adds color rather than covering it up. If you try to dye a blue-and-white striped fabric with yellow dye, you won't get a solid yellow sofa. You'll end up with a green-and-yellow striped sofa. The original pattern will almost always telegraph through, creating a muted or muddy version of what was there before.

To truly transform a pattern into a flawless solid color, your only real path is professional custom upholstery. It’s the single best way to guarantee a clean, high-end result that honors the furniture’s design—a service we proudly offer to clients from Buckhead to Milton.

How Do I Keep Dye from Rubbing Off on My Clothes?

There is nothing worse than standing up from your newly-dyed chair to find its color smeared all over your favorite pants. This problem is called crocking, and preventing it comes down to two critical steps.

First, you have to be relentless with rinsing. After dyeing, rinse the fabric over and over until the water runs completely clear. This removes all the excess, unbonded dye molecules.

Second, you must "set" the dye according to the manufacturer’s instructions. This step, which usually involves heat or a chemical fixative, creates a permanent bond between the pigment and the fiber. Skipping it is a guarantee for stained clothes. It's a key reason why the commercial-grade textiles used in professional upholstery, like those in our Atlanta fabric showroom, are so prized for their superior colorfastness.

What If My Furniture Has Wood or Metal Accents?

Meticulous, painstaking preparation is everything. You have to carefully and completely tape off every single square inch of non-fabric material using high-quality painter's tape and plastic sheeting.

Fabric dye is formulated to be permanent, and it will permanently stain wood, tarnish metal, and ruin any other accent it touches.

Just imagine trying to tape off the intricate, hand-carved legs on an Ambella Home accent chair. The risk of a bleed or a slip of the brush increases dramatically. This is a classic scenario where the precision of an expert is the safer investment, protecting the integrity of your luxury furniture Atlanta piece.

Is It Better to Use a Spray or a Brush?

The right tool depends on the furniture's shape and the fabric's texture. Neither method is universally "better"—they serve different purposes.

-

Spray Application: Sprayers can be great for an even initial coat on large, flat surfaces. But they are notoriously difficult to control. Overspray is a huge risk, and getting even saturation in tufted areas or deep crevices is nearly impossible without creating drips.

-

Brush or Sponge Application: A brush gives you far more control. It lets you physically work the dye into the fibers, which is essential for plush fabrics like velvet or chenille. This hands-on method helps the dye penetrate the weave thoroughly but requires a steady hand to avoid a streaky finish.

Often, the best technique is a combination of the two. A light spray for the base coat, followed by detailed brushwork to ensure complete saturation. This is exactly the kind of detailed work our team providing Atlanta interior design resources can help you navigate.

At Lewis and Sheron Textiles, we believe in empowering you with the knowledge to make confident design decisions. Whether you’re embarking on a bold DIY project or seeking the flawless finish of custom upholstery, our team is here to guide you. Visit our showroom to explore the finest designer fabrics and luxury furniture Atlanta has to offer.

Discover our collections at https://lsfabrics.com.