Think of seam allowance as the hidden framework giving luxury furniture its impeccable shape and lasting durability. It's that essential margin between your stitch line and the raw edge—usually between 1/4 inch and 5/8 inch—and it’s the secret ingredient that separates true craftsmanship from a merely "homemade" look.

In short, getting it right is everything.

Why Seam Allowance is a Designer’s Secret Weapon

Let's skip the dry, textbook definitions. Picture seam allowance as the matting around a priceless piece of art. That border isn't just for show; it adds structure, protects fragile edges, and draws your eye to the center. Seam allowance does the exact same thing for fabric.

It creates the space for strong, resilient seams that handle daily life, whether on a plush Wesley Hall sofa in a Roswell family room or custom drapery catching the light in a Buckhead high-rise. It’s a tiny detail that makes a world of difference in luxury furniture here in Atlanta.

The Foundation of a Flawless Finish

That standard 5/8-inch seam allowance on most patterns isn't an arbitrary number. It’s a pillar of professional pattern making, a trusted dimension that leaves just enough room for strong seam finishes and minor adjustments without creating bulk. This precision is what allows for the perfectly crisp cushion corners and smooth lines you see on a Verellen sofa.

This concept has been a cornerstone of quality since the sewing machine revolutionized textiles in the 1850s. By 1900, with U.S. textile output hitting billions of yards, master artisans learned a hard lesson: improper seams led to shocking waste—sometimes up to 15-20% on custom jobs. This history is why our Atlanta-based workroom obsesses over every millimeter.

Seam allowance isn't just a buffer for your needle. It's the difference between a piece that simply exists and a piece that endures, beautifully. It’s the invisible architecture behind every stunning silhouette.

When you visit our Atlanta fabric showroom, you aren’t just choosing a pattern; you’re selecting a textile with its own personality and needs. Our design experts, serving clients from Alpharetta to Marietta, know that the right seam allowance transforms these exquisite fabrics into timeless investments.

Here’s why getting it right is non-negotiable for a high-end finish:

- Structural Integrity: It prevents seams from pulling apart under daily stress, which is crucial for high-traffic furniture like a Lee Industries chair.

- Fray Prevention: It provides space for professional finishing techniques, keeping raw edges contained and pristine for years to come.

- Design Precision: It's what allows for perfectly matched patterns and smooth, pucker-free curves on even the most complex custom upholstery projects.

Mastering seam allowance is the foundational secret our artisans use to turn a bolt of designer fabric into functional art. It’s a small detail that defines the quality Lewis and Sheron has delivered for decades.

How to Customize Your Seam Allowance for Any Fabric

A standard seam allowance is a fantastic start, but it's not the final word. The true art of luxury upholstery lies in knowing how to tailor that allowance to the specific fabric in your hands. This is how you start to think like a seasoned designer—making confident choices that honor the textile.

The weight, weave, and drape of a fabric are your primary guides. A delicate Belgian linen requires a completely different approach than a robust performance fabric destined for a high-traffic sofa in a Milton family home. Your seam allowance has to respect that difference.

This tiny detail is absolutely critical in high-end design. Imagine transforming your Atlanta living room with exquisite Verellen upholstery from Lewis and Sheron—seam allowance precision is what ensures those timeless pieces fit like a glove. Historically, this wasn't always a given. When we first opened in 1946, seam mismatches caused an astonishing 22% of reworks in custom shops. Today, a tiny 1/4-inch seam variance can lead to an 18% strength loss in high-end weaves, a major compromise in quality.

Matching Fabric Weight to Seam Allowance

The heavier the fabric, the more stress its seams will endure. It's a simple rule of physics that directly impacts your choice. The sturdy textiles used for a Wesley Hall sofa or an Ambella headboard need a little more room to breathe and anchor themselves.

-

Lightweight Fabrics (Sheers, Silks, Voiles): These beauties can't handle bulk. A narrow seam allowance of 1/4 inch (0.6 cm) is ideal. It keeps the seam nearly invisible and preserves the fabric's delicate drape, perfect for elegant window treatments in an East Cobb sunroom.

-

Medium-Weight Fabrics (Cottons, Linens, Chintz): This is where your standard 1/2 to 5/8 inch (1.3 to 1.5 cm) shines. It provides enough space for a strong seam finish without overwhelming the fabric, making it a great choice for custom pillows or light upholstery.

-

Heavyweight Fabrics (Velvet, Canvas, Upholstery-Grade Twill): For the workhorses of luxury furniture, go wider. A 3/4 to 1 inch (2 to 2.5 cm) allowance gives the seam the strength it needs to withstand years of use on a well-loved piece.

How Fabric Weave Affects Your Choice

Beyond weight, the very way a fabric is constructed—its weave—plays a huge role. Loosely woven fabrics are much more prone to fraying, and a narrow seam is practically a recipe for disaster.

A tightly woven textile, like a performance canvas, holds its edge beautifully. But a loosely woven linen or tweed will start to unravel with alarming speed. For these, a wider seam allowance is non-negotiable. It provides the necessary buffer to secure the edges with a robust finish, like serging or a flat-felled seam. Understanding the structure of different weaves is a core design skill. Learning the most common examples of woven fabrics is a great way to build your expertise.

The right seam allowance doesn’t just join two pieces of fabric. It anticipates the fabric’s behavior, protects its integrity, and ensures the final piece achieves the flawless silhouette you envisioned.

This is the level of detail that separates good from exquisite. Whether you're working on a project in Roswell or sourcing fine fabrics in Alpharetta, tailoring your seam allowance to the textile is a hallmark of true craftsmanship. It’s a practice our team at the Buckhead showroom has perfected.

Measuring and Marking with Professional Precision

Luxury lives in the details. A truly flawless finish, whether on a custom sofa or a perfectly tailored drape, doesn’t happen by accident. It all starts with the right tools and an obsession with accuracy.

Before you even think about the allowance itself, the foundation has to be solid. It’s a lot like learning how to measure yourself for a suit; the quick, precise steps at the beginning dictate the quality of the final fit.

Here in our Atlanta workroom, where our artisans craft custom upholstery for clients from Roswell to Milton, precision is everything. We rely on a handful of trusted tools that guarantee crisp, accurate lines, turning beautiful designer fabrics into true masterpieces.

The Artisan’s Toolkit

Forget guesswork. To get that high-end furniture Buckhead showroom quality, you need tools that ensure every measurement is exact and every mark is clear.

- Magnetic Seam Guide: This little gadget is a game-changer. It attaches to your sewing machine’s needle plate, creating a physical edge that guides your fabric for a perfectly straight seam.

- Clear Acrylic Rulers: A quilter’s ruler is an upholsterer's best friend. The transparent grid is indispensable for measuring and marking allowances directly on the fabric.

-

Marking Tools: Use the right marker for your fabric. You want something visible when you need it and gone when you don’t.

- Tailor’s Chalk: A classic for a reason. It’s perfect for marking wools and heavier upholstery fabrics because it brushes away easily.

- Disappearing Ink Pen: Our go-to for lighter-colored or delicate fabrics. The marks simply vanish with a bit of air or water, leaving no trace.

Marking Different Designer Fabrics

Let's be honest: handling a slippery silk is a world away from managing a thick, textured wool. Every fabric requires a slightly different touch. Consistency is the secret sauce for perfectly matched patterns.

When you're tackling a larger project, like creating custom linens, mastering these marking skills is what separates good from great. If you need inspiration, our guide on how to make tablecloths shows how precise measurements translate into a beautiful finished product.

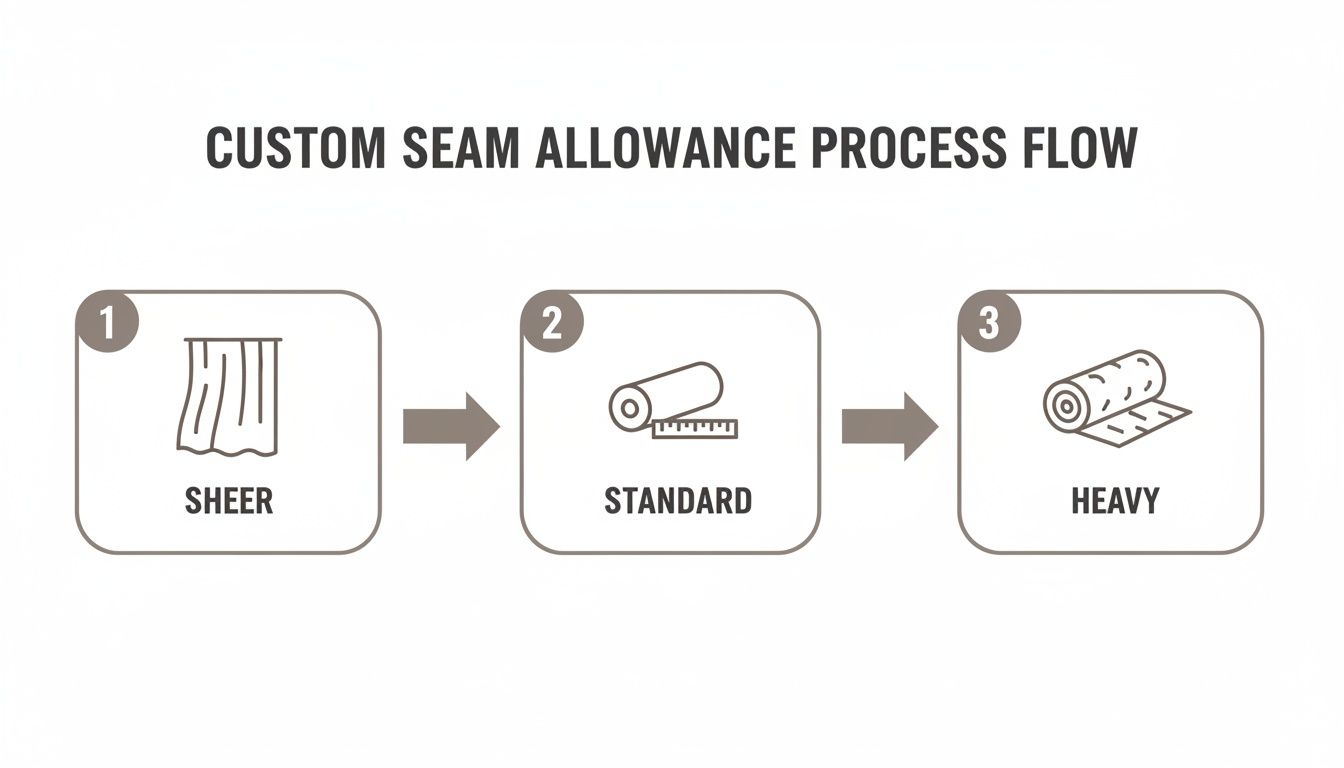

This visual guide breaks down the typical workflow for adapting your seam allowance based on the fabric you're working with, from delicate sheers to heavy-duty upholstery.

As you can see, the heavier the fabric, the wider the seam allowance needs to be to ensure strength and durability.

The accuracy of your marked line is the foundation of your final seam. A wobbly line, no matter how perfectly sewn, will result in a wobbly seam. Take your time here; it pays dividends.

At the end of the day, whether you're an interior designer sourcing for a project in Forsyth County or a homeowner with a passion for quality, mastering these techniques is fundamental. It’s this meticulous attention to detail that elevates a project from simply "made" to truly "crafted"—a core principle behind every piece you’ll find in our Buckhead showroom.

Mastering Professional Seam Finishing Techniques

A beautiful seam is only half the story. The inside finish is what really signals quality and longevity—this is where craftsmanship separates a piece that’s simply put together from one that’s artfully constructed.

This guide will help you elevate your projects from good to truly exceptional. We'll explore the professional seam finishing techniques that do more than just prevent fraying; they add structure, durability, and that clean, high-end look that defines the luxury furniture in our Buckhead showroom.

Beyond the Basic Zigzag and Serger

Almost everyone starts with a simple zigzag stitch or a serged edge. They're quick, functional, and get the job done by neatly encasing the raw edge. A serger, especially, trims and wraps the edge for a tidy finish that’s a staple in modern upholstery.

These methods are the workhorses of the sewing world, and for good reason. They are fast and effective. But for truly exquisite work, particularly with the fine fabrics you’ll find in our Atlanta showroom, there are more elegant solutions.

A truly luxurious piece is beautiful from every angle, inside and out. The finish of a seam allowance is a quiet testament to the artisan's dedication to quality.

Advanced Finishes for a Luxury Touch

Ready to move beyond the basics? These are the sophisticated methods our experts use for high-end furniture and drapery, ensuring every detail reflects superior craftsmanship. These techniques turn the inside of a cushion into a work of art.

-

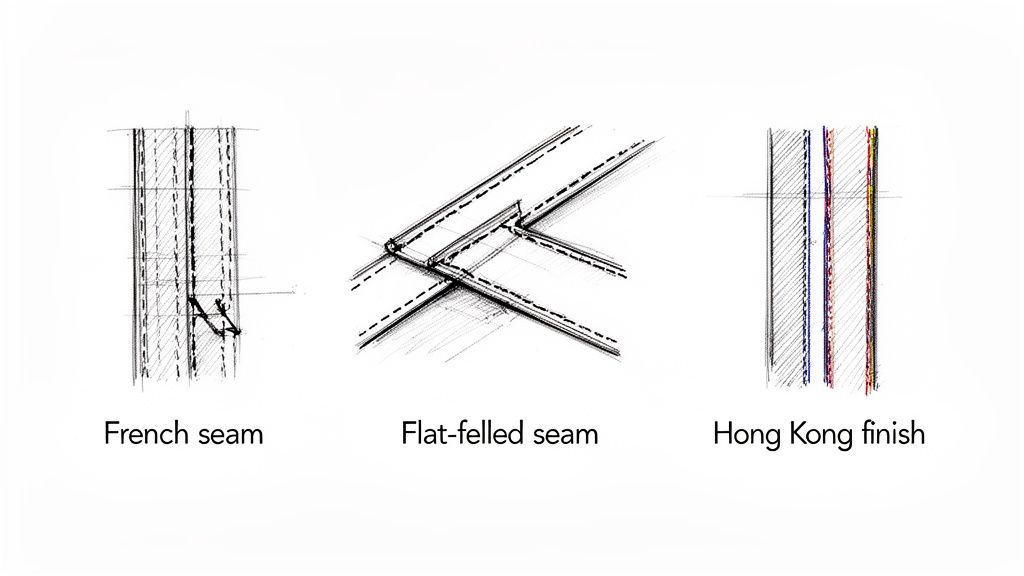

French Seam: The absolute epitome of elegance. A French seam completely encloses the raw edges within a neat, narrow seam, making it perfect for sheer and lightweight fabrics—like the delicate linens you might choose for drapery in a Milton home. It looks flawless from both sides.

-

Flat-Felled Seam: When you need a seam that’s practically indestructible, this is your go-to. The technique involves stitching the seam, trimming one side, then folding the other over it and topstitching it down. It’s incredibly strong and flat, making it the top choice for durable upholstery on brands like Ambella or Wesley Hall.

-

Hong Kong Finish: Think of this as the couture finish for unlined cushions or drapery panels. Each raw edge is individually wrapped in a thin strip of bias tape, sometimes in a contrasting color for a hidden pop of style. It adds structure without bulk and is a clear signal of a meticulously crafted piece.

Choosing the Right Seam Finish

This table breaks down which finish works best for different situations. Think of it as your cheat sheet for matching the right technique to your fabric and project.

| Finishing Technique | Best For These Fabrics | Appearance | Durability Level |

|---|---|---|---|

| Zigzag/Serger | Most fabrics, especially medium- to heavyweight wovens and knits. | Clean, functional, but can be bulky. | High |

| French Seam | Lightweight, sheer fabrics like silk, chiffon, organza, and linen. | Elegant, clean, and enclosed. No raw edges visible. | Medium |

| Flat-Felled Seam | Heavy-duty fabrics like denim, canvas, and heavy upholstery. | Flat, strong, and visible topstitching. | Very High |

| Hong Kong Finish | Medium- to heavyweight fabrics like wool, tweed, and brocade. | High-end, decorative, and clean with bound edges. | High |

Picking the right finish is an art form. A delicate French seam would be lost on heavy upholstery, while a simple serged edge might not do justice to a fine silk.

Consider how decorative details might change your approach. Things like custom welting require a different way of thinking about seam finishing. Our expert guide on adding piping to cushions shows how these elements integrate for a polished, professional look.

This attention to detail is what sets custom furniture apart. It’s a commitment to quality that our trade furniture program partners—like Verellen, Lee Industries, and Wesley Hall—embody. Whether you're an Atlanta interior designer or a discerning homeowner, understanding these techniques helps you appreciate true craftsmanship.

Handling Seam Allowances for Tricky Fabrics

Not every fabric follows the same rules. When you walk through our Buckhead showroom, you’re met with a world of textiles, each with its own personality—from delicate silks to tough-as-nails performance weaves. The secret to working with them is finesse and knowing how to adapt.

Think of this as your insider’s guide to tackling the beautiful but finicky materials you see in the homes of Atlanta’s top interior designers.

The Challenge of Linens and Loosely Woven Textiles

Let's talk linen. A gorgeous Belgian linen from our Libeco collection brings incredible texture to a space, whether it's for drapes in a Milton estate or pillows in an Alpharetta sitting room. But that loose, natural weave means one thing: it frays. A lot. A standard 5/8-inch seam allowance is the absolute minimum.

For fabrics like these, we almost always suggest going wider, closer to 3/4 or even 1 inch, and then finishing with a French seam. This classic technique tucks the raw, fray-happy edge away completely, leaving a finish that’s as clean and durable on the inside as it is on the outside.

Taming Silks and Velvets

Silks and velvets can be the divas of the fabric world. They slip, slide, and will pucker if you look at them the wrong way. The key to handling these luxury materials is control, and your seam allowance is your first line of defense.

Surprisingly, a narrower seam allowance—around 1/2 inch—often gives the best results. Why? It leaves less fabric inside the seam to shift around and cause those annoying puckers. Here’s our approach:

- Pin Generously: Use very fine, sharp silk pins and place them close together. This is not the time to be stingy.

- Walk, Don’t Run: A walking foot on your sewing machine is a non-negotiable. It feeds the top and bottom layers of fabric through at the exact same speed, preventing dreaded shifting.

- Staystitch Curves: Before you sew the main seam on a curve, run a quick line of staystitching just inside your seam allowance. This simple step stabilizes the fabric and keeps it from stretching out of shape.

With delicate fabrics, your seam allowance isn't just a measurement—it's a control mechanism. A slightly narrower, well-managed seam prevents the fabric from misbehaving and ensures a perfectly smooth finish.

Working with Stretch and Knit Fabrics

While not common in traditional upholstery, stretch fabrics are finding their place in modern furniture, especially for slipcovers. These materials require a totally different mindset. Their whole job is to flex, so if you lock them down with a rigid seam, you’ll just end up with popped threads.

For knits and stretch wovens, stick to a much narrower seam allowance, usually just 1/4 to 3/8 inch. This is because the seams themselves need to be able to stretch with the fabric. The most critical part is the stitch itself. You have to use a stitch that can stretch—think a zigzag stitch, a special stretch stitch, or a serger.

Whether you're an Atlanta interior designer or a homeowner diving into an ambitious project, understanding these nuances separates good work from great work. It's the expertise behind our Lewis and Sheron Trade Program and what you see in the flawless custom upholstery on a Wesley Hall sofa. It all comes down to respecting the fabric.

There’s a thrill that comes from a DIY project you’ve absolutely nailed. But every so often, you run into a project where ambition and complexity are at odds. This is where the artisan’s touch becomes non-negotiable—and it’s the perfect moment to trust the professionals.

Knowing when to call in an expert isn’t admitting defeat. It’s making a smart investment in heirloom-quality results. Large-scale projects, like reviving a treasured Wesley Hall sofa or creating floor-to-ceiling draperies for a Buckhead home, are about so much more than sewing a straight line. They’re exercises in structural engineering, pattern alchemy, and flawless finishing.

This is where the true value of a professional shines.

The Art of Flawless Execution

When you bring a project to a professional workroom, like the one that powers our Atlanta fabric showroom, you’re getting access to decades of hard-won skill. This is especially important for the kind of high-end furniture Atlanta designers and homeowners love.

- Perfect Pattern Matching: Making sure a bold print flows seamlessly across the cushions and frame of a Lee Industries chair isn’t luck. It’s a mathematical art form that takes a meticulous eye and years of experience.

- Structural Reinforcement: A professional reupholstery job goes beyond fabric. Our experts inspect and reinforce the frame, swap out worn padding, and re-tie springs, ensuring your beloved piece is not only beautiful but structurally sound enough to last another generation.

- Invisible Finishing: Those flawless seams, perfectly placed welting, and the balanced hang of custom window treatments are the result of techniques perfected over thousands of hours. It’s a level of polish that defines luxury.

Bringing Ambitious Visions to Life

For interior designers in Roswell, Alpharetta, and across North Georgia, our Lewis and Sheron Trade Program is the key to bringing ambitious client visions to life without compromise. It’s an Atlanta interior design resource that unlocks our workroom, exclusive textiles, and premier furniture vendors like Verellen and Ambella.

Entrusting your project to an expert isn’t just about getting it done right. It’s about ensuring the final piece honors the quality of the designer fabrics you’ve so carefully selected.

Our team has the skill to navigate the complexities of custom furniture creation, from the first design consultation to the final stitch. When you’re ready to transform an idea into a timeless piece of craftsmanship, our design services and professional workroom are here to bring it to life.

Answering Your Seam Allowance Questions

Still fuzzy on some of the finer points? You're in good company. We hear these questions all the time from designers and homeowners in our Buckhead showroom, so let's clear them up.

Should I Press Seams Open or to One Side?

For the vast majority of upholstery work, pressing seams open is the way to go. Think of it like butterflying a chicken—it distributes the bulk evenly. This creates a much flatter, almost invisible seam, which is absolutely critical for getting that sleek, professional finish on a high-end piece like a Verellen sofa.

There are exceptions. For delicate or sheer fabrics, pressing the seam to one side can add a bit of strength. The most important thing, whichever method you choose, is to be consistent across the entire project.

How Do I Handle Bulky Seams on Heavy Fabric?

Heavy-duty fabrics, like the robust textiles on a Wesley Hall or Lee Industries chair, are fantastic for durability but can create bulky seams. The secret weapon here is a technique called grading the seam allowance.

Grading simply means trimming the different layers of the seam allowance to different widths. The layer closest to the outside stays the widest, while you trim the inner layers a little shorter. This creates a gentle, staggered slope instead of a hard ridge, letting your curves and corners lay beautifully flat. It's a non-negotiable technique that our trusted Atlanta interior design resources recommend for all high-end upholstery.

What Is the Best Way to Trim Allowances on Curves?

Getting a perfect, pucker-free curve is all about two little actions: clipping and notching.

For an inward curve (a concave curve), cut tiny triangular wedges, or notches, out of the seam allowance. This removes the extra fabric that would otherwise bunch up.

For an outward curve (a convex curve), make small, straight cuts, or clips, into the seam allowance, stopping just short of the stitch line. This allows the fabric to spread apart and lie flat when you turn it. This tiny detail is one of the most important lessons in our seam allowance guide for creating those flawless edges.

Ready to transform your vision into a timeless piece? The designers at Lewis and Sheron Textiles are here to help you select the perfect designer fabrics and custom furniture for your home. Explore our Atlanta fabric showroom and design services today.