Reupholstering furniture isn’t just a project; it’s a revival. You’re not just swapping old fabric for new. You’re giving a piece with history a new story—fortifying its frame, renewing its comfort, and dressing it in exquisite fabric. This is where true craftsmanship and design collide, turning a forgotten piece into a custom treasure.

Is Your Furniture Worth Reupholstering?

Before you start dreaming of designer fabrics from our Atlanta fabric showroom, let’s talk bones. Not every piece of furniture is a candidate for a second act. The secret to a successful project—one that becomes a family heirloom, not a headache—is the quality hiding underneath. Think of the stunning collections from brands like Verellen or Wesley Hall; their timeless appeal starts with a rock-solid foundation.

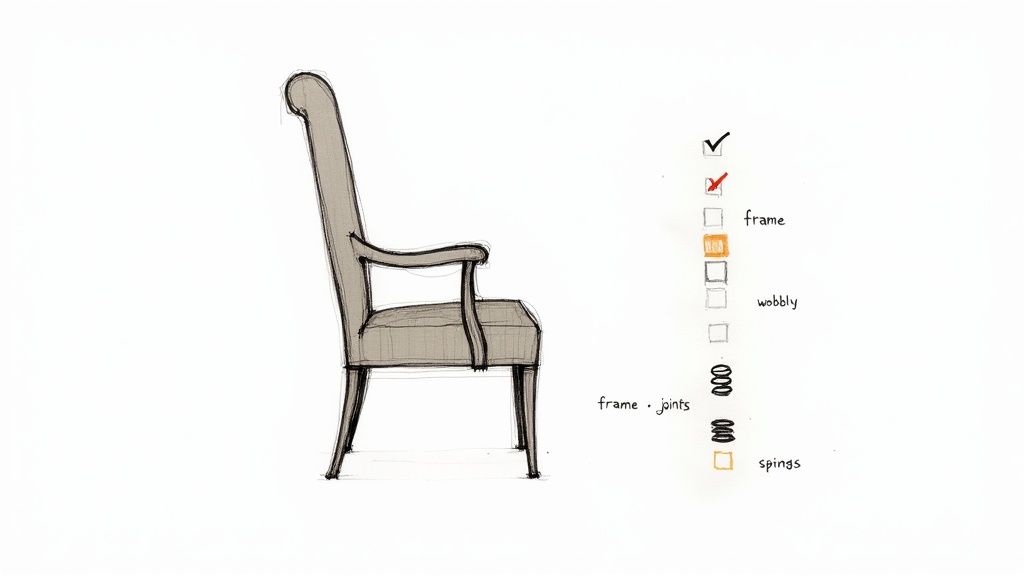

Your first mission: play detective. Flip the piece over. Push on the arms. Sit on it. Listen. Does it feel substantial? Or does it creak like a haunted house? This initial hands-on assessment is what separates projects worth your time from those better left on the curb.

The Frame: The Soul of the Piece

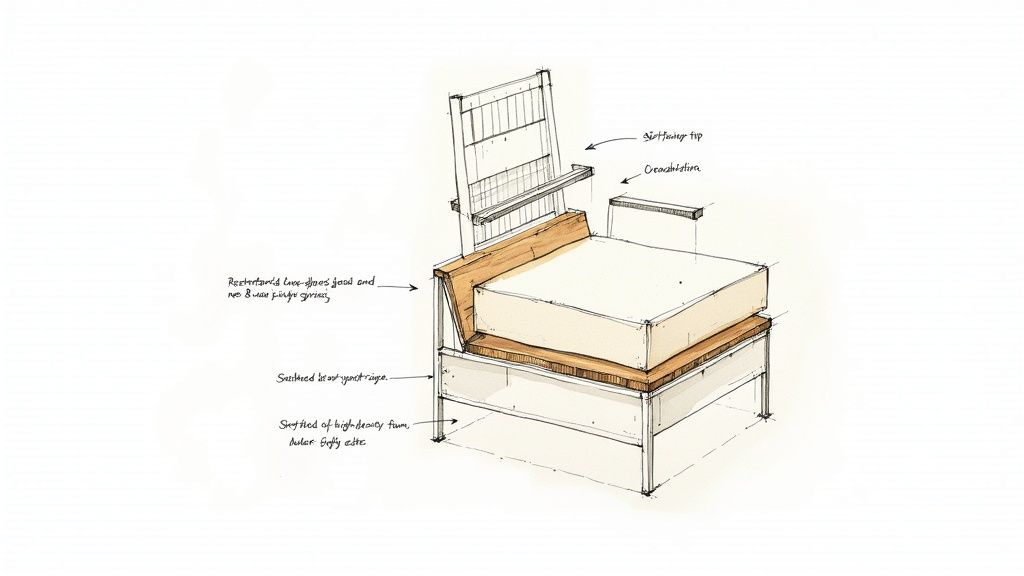

Honestly, the frame is everything. High-end furniture, the kind you find in discerning homes from Buckhead to Alpharetta, is almost always built on solid hardwood frames—oak, maple, or ash. These pieces are held together with sturdy dowels or mortise-and-tenon joints, not flimsy staples.

Give it the “wobble test.” Grab the arms and give them a firm shake. If it feels loose, the joints are failing. Minor fixes are one thing, but a completely compromised frame isn’t worth the investment of your time, let alone fine fabrics.

Here’s your quick frame inspection checklist:

- Wood Quality: Solid hardwood is the goal. Avoid particleboard or MDF. They lack the durability to hold staples and stand the test of time.

- Joint Construction: Peek at the corners. See those triangular blocks? That’s a classic sign of quality craftsmanship, the kind you’d expect from a Lee Industries chair.

- Overall Condition: Surface scratches are cosmetic. Deep cracks, splits, or wood rot are deal-breakers.

Springs and Support: The Heart of Comfort

Next, the support system. Press down on the seat. Does it push back with supportive springs, or does it sink? The best pieces feature an eight-way hand-tied spring system—the gold standard for comfort and longevity. If the springs are broken or sagging, they’ll need replacing, which definitely ramps up the difficulty.

A piece with good bones and classic lines is always a prime candidate for custom upholstery. You're not just saving furniture; you're creating a custom element for your home that no big-box store can replicate.

Before you commit, you might explore professional couch upholstery cleaning techniques. Sometimes, a deep clean is all it takes. But if the fabric is shot and the frame is solid, you’ve got a winner. This careful evaluation ensures your hard work—and your investment in beautiful fabric—is built on a foundation of quality.

Gathering Your Professional Upholstery Toolkit

Want a finish that looks like it belongs in a high-end furniture store in Buckhead? You need the right tools. Tackling a luxury furniture project with a craft-store staple gun is a recipe for disaster. Pros get professional results because they use professional-grade equipment. It's that simple.

Think of it this way: the designer fabrics you find in our Atlanta fabric showroom are the star. Your tools are the critical supporting cast. Skimping here is a mistake that will absolutely show in the final product.

The Essential Tools for Disassembly and Assembly

First comes demolition, done with a surgeon’s precision. Then, careful reassembly. These tools are non-negotiable.

- Heavy-Duty Staple Remover: This isn't your office tool. A proper upholstery staple remover gets under stubborn staples without gouging the wood frame of your Wesley Hall sofa.

- Needle-Nose Pliers: For the staples that inevitably break or refuse to budge.

- Pneumatic Staple Gun: A manual gun leaves your hands aching and staples sitting proud. A pneumatic gun drives them deep and flush, creating that tight, secure finish essential for custom upholstery.

- Upholstery Shears: Don't even think about regular scissors. True upholstery shears are heavy and sharp, designed to cut through dense textiles like butter. They’re key to clean, fray-free edges.

The Foundational Materials for Comfort and Structure

What’s on the inside counts just as much. The finest Lee Industries chairs aren't just beautiful; they're built for incredible comfort, which starts with quality internal materials.

You’ll need to assess and likely replace the guts of your piece. Here’s what to have ready:

- High-Density Foam: This provides the firm, supportive base for seats. Density is what determines how well it holds its shape.

- Cotton Batting & Dacron Wrap: Batting softens the hard edges of the foam and frame. A final Dacron wrap gives cushions that plush, crowned look and helps fabric slide on smoothly.

- Jute Webbing & Cambric Dust Cover: Webbing creates the supportive base. Cambric is the black fabric stapled to the underside that gives it a clean, finished look.

- Upholstery Tack Strip: For creating crisp, straight edges without visible staples, a flexible tack strip is a pro’s secret weapon. We recommend a quality upholstery blind tack strip for flawless lines.

Assembling the right toolkit is an upfront investment, but it's the difference between a DIY struggle and a rewarding, professional-quality outcome. These are the same tools our experts use for custom upholstery projects for clients from Roswell to Marietta.

The process of reupholstering high-end furniture is a significant undertaking. Cost can vary widely based on the furniture's complexity and the materials you choose. For perspective, a professional job on a standard sofa in the U.S. can range from $500 to $2,000, with luxury or custom projects costing significantly more. Understanding the market helps you appreciate the value you're creating.

The Artful Takedown: Deconstructing with Precision

Now for the most satisfying part: demolition. But let’s be clear—this is surgical deconstruction, not a free-for-all. You’re reverse-engineering the piece, and if you do it right, reassembly will be a thousand times easier.

Your goal is to remove every piece of fabric in large, intact sections. These old pieces aren't trash; they're your patterns. Resist the urge to rip and tear. Patience now pays off big time later. Trust me.

This is your chance to see how a well-made piece of furniture was put together.

As you can see, every phase builds on the one before. A careful takedown is the only way to ensure a flawless finish.

Uncovering the Past, One Staple at a Time

Start by flipping your piece upside down and removing the cambric dust cover. Now you’ll see how the layers were originally applied.

The golden rule of reupholstery: the last piece of fabric that went on is the first one that comes off. This usually means starting with the outside back, then the outside arms, inside arms, inside back, and finishing with the seat deck.

As you work, you’re creating a roadmap. Here’s how the pros do it:

- Document Everything: Before you touch a single staple, take photos. Lots of them. Get every angle, every corner, every tricky fold. This visual diary will be your best friend later.

- Label Fanatically: When you take a piece of fabric off, grab a marker and label it immediately. "Inside Left Arm - TOP." This removes all guesswork.

- Save Everything (For Now): Don’t toss the old cording or tack strips. They all hold clues about how the original upholsterer achieved a certain shape or a crisp edge.

Mastering the Art of Staple Extraction

You are going to remove hundreds, if not thousands, of staples. Doing this without splintering the wood is a skill.

Use your staple remover to gently pry up one side. Then, grab your needle-nose pliers and pull it straight out. Wiggling it will just snap it, leaving a sharp piece of metal stuck in the wood.

Think of yourself as an archaeologist carefully uncovering a treasure. Every layer removed reveals a secret about the piece's construction—a masterclass in how quality furniture is made.

This careful process is what separates a DIY-looking project from a professional custom upholstery job worthy of a spot in any Marietta or Milton home. You're preserving the "DNA" of the original design. By saving the old fabric as templates, you guarantee that every curve of an Ambella accent chair or the clean lines of a Lee Industries sofa are perfectly replicated.

Building a Solid Foundation with Frame Repair and Padding

Once stripped, you see what your furniture is really made of. This is the moment of truth. You’re looking at the raw structure, and you have the perfect opportunity to make it stronger than it has been in years. We're not aiming for a cosmetic facelift; we're giving it another fifty years of life.

Now's the time to get hands-on. Inspect every inch for weaknesses. Don't be shy—give it a good shake. You're hunting for loose joints where the wood has separated. These are future creaks you can silence for good.

Reinforcing the Frame for Lasting Strength

If a joint feels loose, fix it. Grab some quality wood glue and clamps.

Carefully work wood glue into the joints. Clamp them tightly and wipe away any excess. Let it cure for a full 24 hours. This simple step transforms a shaky frame into a single, solid unit—the kind of structural integrity you’d find in a high-end furniture store on West Paces Ferry.

While you're at it, inspect the corner blocks. If they're loose, re-glue and secure them. Solid corner blocks are a tell-tale sign of quality construction, often found in luxury furniture from Atlanta’s top designers.

The Heart of Comfort: Springs and Webbing

Next, the support system. This is where comfort is born.

Many high-end pieces, like a classic Wesley Hall sofa, feature 8-way hand-tied springs. This method is the gold standard for a reason. Each spring is tied to its neighbors and the frame in eight directions, creating a web that distributes weight perfectly. If you see broken twine, you'll need to re-tie them. It’s meticulous, but it creates that unparalleled, supportive sit.

If your piece uses jute webbing, test the tension. It should be taut. If it’s sagging, replace it.

Don't be tempted to skip these repairs. The most exquisite designer fabrics in the world won't hide a wobbly frame or a sagging seat. The foundation is everything.

Layering Padding Like a Pro

With a rock-solid structure, it’s time to build back comfort. This is how you elevate a piece from looking new to feeling truly custom and plush—worthy of any high-end Roswell or East Cobb home.

It starts with the right foam. For seat cushions, high-density foam is non-negotiable; it prevents sagging for years. Match the original thickness, or add an inch for extra comfort.

Next comes the Dacron wrap. This fluffy polyester is the secret ingredient.

- Softens Edges: Wrap a layer of Dacron over the foam and any hard edges on the frame. This prevents the fabric from rubbing against the wood.

- Creates a Crowned Look: For cushions, Dacron on the top and bottom gives them that beautiful, rounded "crowned" shape. It’s a subtle detail that screams quality.

- Aids in Application: The slick surface of Dacron helps your new fabric slide into place smoothly.

After the Dacron, add a layer of cotton batting for extra softness. Layering these materials is an art. The goal is to build smooth, inviting contours that will support the final fabric beautifully. This work ensures your upholstery project not only looks incredible but feels like the luxury furniture it was always meant to be.

Choosing The Perfect Designer Fabric

This is where the real magic happens. If the frame is the soul, the fabric is its heart—and its entire personality. Picking the right fabric is more than finding a pretty color; it's balancing looks and lifestyle to create custom upholstery worthy of Atlanta's finest homes.

It's easy to get swept away by looks alone. In our Buckhead showroom, we see it all the time. But the real work begins when we discuss how you live. A Wesley Hall sofa for a busy family room in East Cobb requires something different than a delicate Ambella accent chair for a quiet study.

The global upholstered furniture market is thriving for a reason. People are investing in pieces that last. The U.S. market is projected to hit $27.64 billion by 2030. Sofas are most popular, making up 35% of sales, but chairs are the fastest-growing category. This tells us homeowners are curating their spaces with unique statement pieces, making fabric selection paramount.

Decoding Durability With Double Rubs

One of the most critical metrics for any designer fabric is its Wyzenbeek test result, or "double rub" count. This number tells you exactly how durable a fabric is. An abrasive pad is rubbed back and forth over the fabric until two yarns break. Each pass is one "double rub."

Here’s a simple breakdown:

- Delicate Duty (Under 10,000): For decorative pillows or accents that won't see daily handling.

- Residential Use (15,000 - 30,000): The sweet spot for most household furniture.

- Heavy Duty (30,000+): What you need for the family workhorse—the main sofa, a favorite armchair. It’s not uncommon for performance fabrics to have counts well over 50,000.

Calculating Yardage And Mastering The Pattern Match

There's nothing worse than running out of fabric halfway through a project. While online charts give a rough idea, the most reliable way to calculate yardage is to use your old fabric pieces. Lay them out and measure the total area they occupy.

Pro Tip: Always, always buy 15-20% more fabric than you think you need. This buffer saves you from cutting mistakes and is essential for patterns. For large repeats, you might need 30% extra.

Speaking of patterns, getting them to flow seamlessly is a hallmark of high-end custom upholstery. As you cut, lay your templates on the new fabric and take time to ensure the pattern aligns perfectly with adjacent pieces. It’s painstaking, but it separates a professional finish from an obvious DIY job. For a more detailed breakdown, exploring the best fabrics for upholstery is a great next step.

Exclusive Resources For The Trade

For Atlanta's interior design professionals, sourcing that perfect textile sets a project apart. The Lewis and Sheron Trade Program offers exclusive access to designer fabric collections you won't find anywhere else. This is where designers serving clients from Milton to Forsyth County discover the unique textiles that elevate their projects from beautiful to unforgettable. For more in-depth advice, don't miss our guide on choosing the right upholstery fabric.

Knowing When to Call an Atlanta Upholstery Pro

Let’s be honest. There’s a point where passion meets prudence. While you can achieve a stunning result on many pieces, some projects demand a master's touch. This isn't admitting defeat; it's making a smart investment in perfection.

Recognizing your limits is a skill. Certain pieces are too complex or valuable to risk a mistake. If your project involves deep diamond tufting, intricate channel backs, or matching a tricky pattern across curved surfaces, it might be time to step back. These techniques take years of practice to get that flawless finish you see in designer showrooms.

When the Stakes Are Too High

Priceless antiques are another major consideration. That vintage piece from a Roswell estate sale might have a delicate frame where one misplaced staple could cause irreparable damage. The value of professional craftsmanship—the kind we’ve honed for decades here in Atlanta—is in the flawless execution and structural integrity only experience can guarantee.

This is about protecting your investment. For an heirloom piece or complex design, professional custom upholstery isn't an expense; it's insurance for an exquisite, lasting result that honors the furniture's legacy.

The Value of a Master’s Touch

With the rising cost of new luxury furniture, professional reupholstery has become an increasingly smart decision. Investing in an expert refresh for a piece with good bones just makes sense.

This trend is growing. A National Upholstery Association’s 2025 Pricing Survey found the median price for reupholstering with a client's own material jumped from $15 to $25 per yard in just two years. It highlights the value people place on skilled labor.

Our custom upholstery services in Atlanta are designed for these exact situations. We handle the intricate work, from perfect welt cords on a Wesley Hall sofa to the delicate restoration of a family treasure. You get the peace of mind that comes from knowing your project is in the hands of artisans, resulting in a bespoke piece that is nothing short of art.

Common Questions About Reupholstering Furniture

Even seasoned designers have questions when it comes to the nuances of custom upholstery. Here in our Buckhead showroom, we hear a few key queries pop up again and again.

One of the biggest anxieties is how much fabric to order. While yardage charts give you a ballpark, the most accurate method is to use your old fabric as a template.

Lay out all the pieces, measure the total area, and then add at least 15-20% extra yardage. This isn’t optional—it's your safety net for pattern matching, making welt cord, and fixing mistakes. If you've fallen for a bold, large-scale print, you'll need to budget for even more.

Durability and Lifestyle Considerations

Another constant question is about durability, especially for busy family homes in Roswell or Alpharetta. If you’re redoing a high-traffic piece like a family room sofa, you must look at performance fabrics.

These textiles are engineered for real life, resisting stains and fading with ease. Look for a high "double rub" count—anything over 30,000 is fantastic for heavy-duty use. The best part? Modern performance collections offer the gorgeous look of linen or velvet, so you don't sacrifice style for strength.

Before stepping into our Atlanta fabric showroom, it helps to get your thoughts in order. We've put together a great resource for this—check out these 10 questions to ask when choosing upholstery.

A common myth we love to bust is that you can't reupholster a leather piece with fabric. You absolutely can! It’s a brilliant way to completely change the personality of a chair or sofa. The process is the same; just be ready to add extra padding to get that soft profile fabric is known for.

Ready to start your own transformation? Visit Lewis and Sheron Textiles in Atlanta to explore our unparalleled collection of designer fabrics and fine furniture. https://lsfabrics.com