Forget everything you think you know about DIY. Crafting a couch cushion isn't just about sewing. It's about starting with an uncompromising vision—sourcing elite materials and mastering a few key construction techniques.

The entire process boils down to this: select the right high-density foam, choose a designer fabric that speaks to your space, cut with precision, and sew a durable, perfectly fitted cover.

It's a true art that balances form and function. Let's get into it.

The Foundation of a Showroom-Quality Cushion

Before you thread a single needle, let's talk about the real secret. It's what separates a passable home project from a bespoke masterpiece worthy of a Buckhead estate.

Your sewing skills matter, but your sourcing strategy matters more. The foam you select and the fabric you choose are the cornerstones of a cushion that looks and feels luxurious for years. This isn't a quick fix; it's about crafting an heirloom.

You need to think like an Atlanta interior designer, considering not just color, but the texture, durability, and drape of exquisite textiles.

Sourcing Materials with a Designer's Eye

Picture the curated comfort of a Wesley Hall sofa or the timeless lines of a Lee Industries chair. That magic starts with the materials. Your project’s success hinges on making deliberate choices from the get-go.

Ask yourself the right questions:

- Will this cushion live in a high-traffic family room in East Cobb or a formal sitting area in a Roswell manor?

- Does the fabric need to stand up to afternoon sun, pets, or energetic kids?

- What kind of comfort are you aiming for—the firm support of a brand-new sofa or the sink-in luxury of a down-wrapped cushion?

This little pre-flight check ensures your project has the DNA of high-end design baked right in. It’s how you create a piece that feels like it came from one of the best high-end furniture stores in Buckhead, not just assembled at home.

The difference between "good" and "unforgettable" lies in the quality of your foundation. A premium foam core and a bolt of fine fabric from our Atlanta fabric showroom are investments in longevity and style.

Responding to a Discerning Market

This focus on exceptional quality isn't just a design principle; it’s what discerning clients demand. The global cushion market is projected to hit USD 23.94 billion by 2035, and a key driver is the growing desire for eco-friendly and organic materials.

Nearly 45% of cushion purchases are now cotton or bamboo, with 35% of buyers actively choosing plant-based or certified organic options. This trend aligns perfectly with the sustainable luxury homeowners and designers seek when they commission custom upholstery. Sourcing fine fabrics from mills like Libeco Home from our Buckhead showroom caters directly to this demand for thoughtfully made, high-quality furnishings. You can read the full research about cushion market trends to learn more.

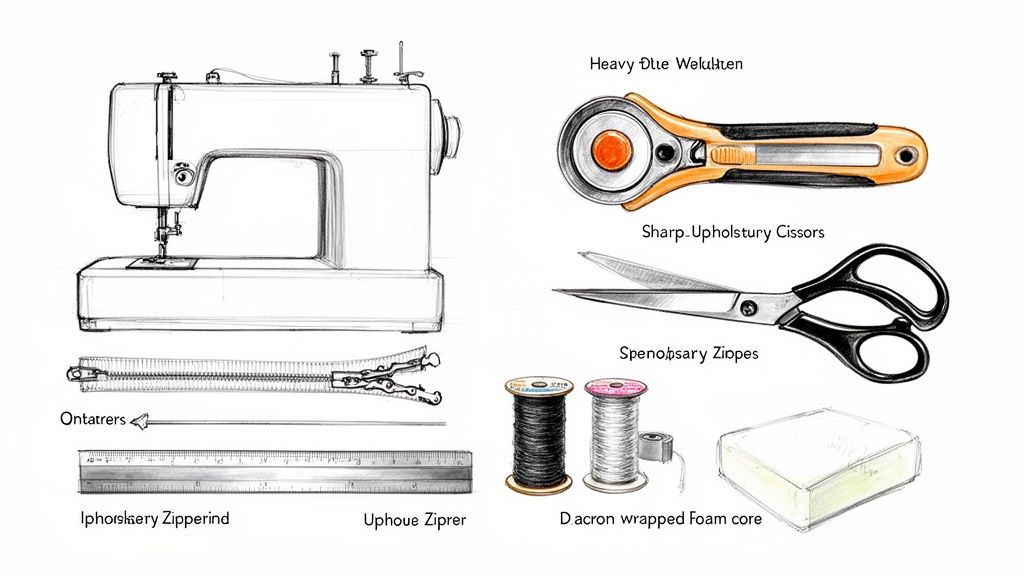

Assembling Your Professional Toolkit and Materials

Every master craftsman relies on the right tools. Want to create a cushion that rivals the luxury furniture you see in a Buckhead showroom? You need an arsenal that goes far beyond a basic sewing kit. This is about precision, power, and the kind of quality top Atlanta upholsterers swear by.

Forget that flimsy machine from high school. You need a heavy-duty workhorse—one that can stitch through multiple layers of upholstery-weight fabric without skipping a beat. It’s absolutely essential for the tight, durable seams you see on Verellen furniture.

And while you're at it, trade your old scissors for a rotary cutter and a self-healing mat. This duo delivers razor-sharp, perfectly straight cuts that are nearly impossible to get by hand. It’s a small detail that makes all the difference between "homemade" and "handcrafted."

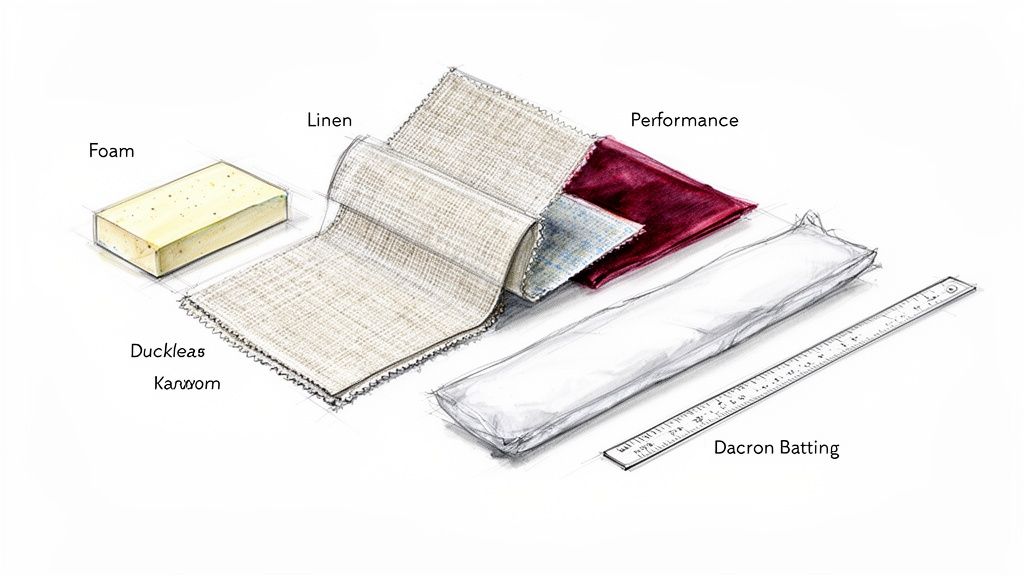

The Anatomy of a High-End Cushion

Beyond the tools, your materials are the soul of your cushion. This is where you channel the spirit of high-end furniture design.

Let’s talk internals. The secret to that plump, inviting silhouette isn’t just foam—it’s a carefully constructed core.

- High-Density Foam: This is your foundation. It provides the firm, lasting support that prevents sagging and ensures the cushion holds its shape for years.

- Dacron Batting: Wrapping your foam core in Dacron is the pro trick for a soft, crowned top. It also helps the cover slide on smoothly and protects the foam from friction.

This combination creates a cushion that not only looks incredible but feels supportive and comfortable—mirroring the quality you’d expect from premium furniture makers.

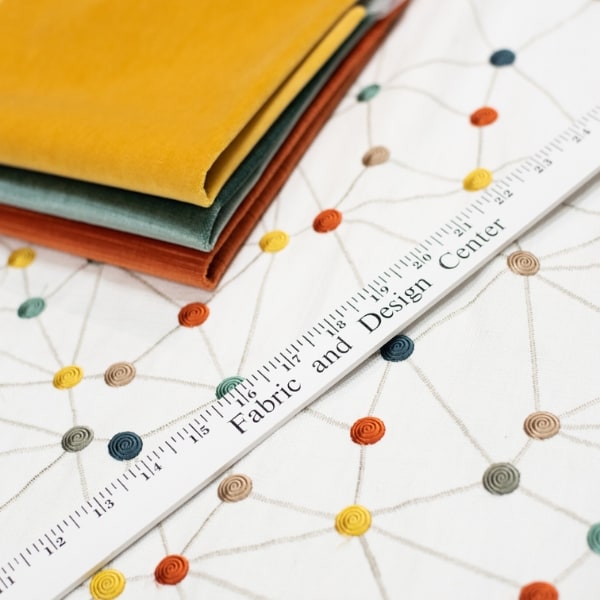

Curating Your Fabric in Our Atlanta Showroom

Now for the main event: the fabric. This is your chance to make a statement. Think of our Atlanta fabric showroom as your personal design library, a treasure map to a world of textures, colors, and performance capabilities.

When selecting your material, exploring options like high-quality fabric by the yard is key. Consider the room's purpose. A busy Marietta family room with kids and pets practically begs for a resilient Crypton performance fabric, which resists spills and stains with ease.

For a formal living space in a Milton or Alpharetta home, nothing compares to the understated elegance of a Belgian linen from Libeco. Its rich texture and sophisticated drape create an atmosphere of quiet luxury. We've put together a complete guide to help—get more expert advice on choosing the right upholstery fabric in our article.

Your toolkit isn't just what's in your sewing box; it's the quality of every component. From the thread and zippers to the foam and fabric, each choice contributes to the final masterpiece.

Designers in our Lewis and Sheron Trade Program get this. They know sourcing the right designer fabrics is the first step in creating custom upholstery that delights their clients, whether they’re in Cumming or right here on East Paces Ferry. Your project deserves that same level of intention.

Mastering the Perfect Cut and Seam

Alright, this is where the artistry begins. You’ve selected a stunning designer fabric from our Atlanta showroom. Now it's time to translate that vision into a perfectly tailored cover.

Forget intimidating instructions. We're breaking this down with clear, practical advice from our own workroom. This is the difference between a simple DIY project and a piece of custom upholstery that belongs in a high-end Buckhead furniture gallery. Get this right, and a flawless finish is practically guaranteed.

Calculating Your Fabric Dimensions

First, measure your foam insert. Then, do it again. Accuracy here is non-negotiable. Grab your tape measure and get the precise length, width, and depth of your foam core.

With those numbers, it’s time for simple math. You need to calculate the final dimensions for each piece of fabric, including a seam allowance. This extra fabric around the edges gives your cushion its strength.

For almost any upholstery project, a 1/2-inch seam allowance is the professional standard. It creates a strong, durable seam that can handle the stress of a snug fit without being too bulky.

Let's walk through an example. Say your foam is 24" long, 24" wide, and 5" deep. For a classic boxed cushion, you’ll cut a top panel, a bottom panel, and side panels (the boxing or gusset).

The key is adding your seam allowance to every side that will be sewn. This means adding 1 inch total to both the length and width for your top and bottom panels (1/2 inch on all four sides). For a deeper dive, our comprehensive seam allowance guide breaks down all the nuances.

Here's a cheat sheet for calculating the fabric pieces for a standard boxed cushion. This little table has saved me from costly mistakes more times than I can count.

Essential Measurements for Boxed Cushions

A quick-reference guide for calculating the fabric needed for a standard boxed cushion, ensuring no material is wasted.

| Cushion Part | Measurement Formula | Pro Tip |

|---|---|---|

| Top & Bottom Panels | (Cushion Length + 1") x (Cushion Width + 1") | Cut two identical pieces. Always double-check your pattern direction on both. |

| Front Boxing Panel | (Cushion Width + 1") x (Cushion Depth + 1") | This is the piece everyone sees. Center any prominent pattern motif here. |

| Side Boxing Panels | (Cushion Length + 1") x (Cushion Depth + 1") | You'll need two. Cut them together to ensure they are perfectly identical. |

| Back Zipper Panels | (Cushion Width + 1") x [(Cushion Depth / 2) + 1"] | Cut two. This formula creates the two halves that will be sewn around the zipper. |

Using these formulas ensures every piece fits together perfectly, giving you that crisp, professional look.

The Two Classic Cushion Styles

While variations are endless, most high-end cushions boil down to two fundamental styles. Each has a distinct personality and requires a slightly different approach.

- The Knife-Edge Cushion: Clean, modern, simple. Made from just two pieces of fabric sewn directly together, creating a single, crisp seam. An incredibly chic choice for throw pillows or relaxed seating.

- The Boxed Cushion: The gold standard for luxury furniture, from Verellen sofas to Wesley Hall sectionals. It has a top, bottom, and separate side panels (the boxing) that give the cushion its defined shape and depth. A sophisticated and timeless look.

For a true showroom-quality piece, the boxed cushion is the style to master. It demands more precision but delivers that unmistakable high-end, structured finish that designers in Roswell and Marietta are always looking for.

Mastering Professional Sewing Techniques

Now for the fun part: construction. The details separate amateur from professional. We're talking crisp corners, an invisible zipper, and perfectly straight seams.

A hidden zipper is a hallmark of quality. Instead of sewing it into a main seam, the pros create a dedicated zipper placket. You cut the back boxing panel into two strips, sew the zipper neatly between them, and then incorporate that unit into the cushion. The result is a closure that’s practically invisible.

Another technique that instantly elevates your project is welt cording, or piping. This fabric-covered cord defines the seams, adds structure, and provides a serious dose of polish. Making your own from your main fabric ensures a perfect, cohesive designer look.

Simply cut long fabric strips on the bias (45-degree angle), wrap them tightly around the cording, and sew it shut with a zipper foot. Then sandwich this finished cord between your fabric panels as you sew. The aesthetic payoff is huge.

Insider Tips from the Workroom

Crafting custom upholstery is a skill honed over thousands of hours. Here are a few essential tips we share with designers in our Trade Program to ensure their client projects in Forsyth County or Milton are impeccable.

First, press your seams. I mean it. At every single stage, take your project to the ironing board and press the seams open. This makes your seams lie perfectly flat, reduces bulk, and gives you a much crisper finish. It’s non-negotiable in any professional workroom.

Second, stop your fabric from shifting. When sewing long seams, especially with slippery or heavy fabrics, the layers can slide. Use plenty of pins or, even better, a handful of upholstery clips to hold everything securely. This guarantees your patterns stay aligned and your seams remain perfectly straight.

Finally, take your time on the corners. Getting sharp, 90-degree corners is all about precision. Sew right up to the turning point and stop with the needle down. Lift the presser foot, pivot the fabric, lower the foot, and continue. Clipping the corner of the seam allowance before turning removes excess bulk, letting the corner pop into a perfect point.

Apply these techniques, and you'll build a cushion that looks like it came straight from a luxury furniture workroom on Collier Rd.

Choosing the Soul of Your Cushion: Foam and Fill

A stunning designer fabric catches the eye, but what’s inside makes you fall in love. The foam and batting are the soul of the piece—defining its comfort, support, and longevity. Think of it as the engine under the hood of a luxury car; it's all about performance.

Let's demystify upholstery foam. For the firm, resilient support found in high-end Wesley Hall sofas, you want a high-density (HD) foam. This is the workhorse that prevents sagging and keeps a crisp silhouette, making it a go-to for designers crafting custom upholstery in Buckhead.

The Secret to a Crowned, Plush Finish

Ever wonder how luxury cushions get that perfect, softly rounded shape? The secret is a layer of Dacron batting. Wrapping your foam core in this fluffy polyester material creates a beautiful "crowned" surface. This simple step softens the hard edges of the foam and gives the cushion that irresistible, plump look.

It’s not just for looks, either. The batting keeps the fabric from shifting and wrinkling, so your custom cushion looks perfectly tailored. This detail is non-negotiable in any professional workroom, from Collier Rd to West Paces Ferry.

The whole process hinges on getting three things right: measure, cut, and sew.

Mastering each stage is what separates a homemade project from a high-end, professional result.

The Ultimate in Sink-In Comfort

For those who crave that cloud-like, sink-in feeling, the answer is down and feather. A hallmark of high-end furniture from makers like Verellen, a down-and-feather-wrapped core offers unparalleled luxury. This construction usually features a supportive foam center enveloped in a channel-stitched casing filled with a blend of down and feathers.

This is the plush comfort that interior designers in Alpharetta and Roswell specify for their most discerning clients. It creates a relaxed, inviting aesthetic that perfectly complements the fine fabrics in our Atlanta showroom.

Your choice of fill isn't just a detail; it's the heart of your cushion. It dictates whether the piece feels firm and supportive or soft and enveloping. A great cushion feels as incredible as it looks.

This commitment to quality components sets American-crafted custom upholstery apart. The worldwide furnishings market hit a staggering $32.1 billion in 2024. While a few countries dominate mass production, the U.S. stands out as the largest importer by value. The price gap is significant: the average import price is $6,624 per ton, while the average export price is $10,694 per ton. This highlights the immense value placed on superior craftsmanship and materials, reinforcing why clients invest in premium makers like LEE Industries for pieces built to last. You can discover more insights about the global furnishing market on IndexBox.

Adding Finishing Touches That Define Luxury

A well-made cushion is impressive. A beautifully finished one is unforgettable. This is where real craftsmanship elevates your project from a handmade item to a high-end piece of custom upholstery.

These are the details that separate amateur work from the bespoke pieces sought by Atlanta's top interior designers. It’s about adding those final, defining touches that signal undeniable quality and a sophisticated eye.

The Art of Button Tufting

Picture the classic, diamond-patterned depth on a gorgeous piece from the Ambella Home Collection. That’s the timeless art of button tufting, and you can absolutely master it. Tufting is structural; it pulls the fabric taut against the cushion fill, creating elegant indentations while preventing the fill from shifting.

To get this classic look, you’ll need a few specialized tools:

- An upholstery needle: Long, heavy-gauge, and designed to push through thick layers without breaking a sweat.

- Tufting twine: A waxed, heavy-duty string that's incredibly strong.

- Fabric-covered buttons: Create these yourself using a button kit and scraps of your main fabric for a seamless, professional look.

The process requires patience. You’ll mark a precise grid, thread the twine through the foam and fabric, secure it with a button, and pull it tight from the bottom. The result is a piece with incredible character, a silhouette that would feel right at home in a luxury Roswell residence.

Elevating with Decorative Trims and Piping

Details make the design. The right trim can instantly transform a simple cushion into a statement piece. Our Buckhead design center is a playground for interior designers for this reason, offering an incredible collection of embellishments from houses like Samuel & Sons.

Imagine a simple linen cushion framed with a modern leather band—it becomes architectural and bold. Or a plush velvet cushion finished with an elegant fringe, adding a touch of old-world glamour. These are integral design choices that add layers of texture and personality.

Piping, or welt cording, is another non-negotiable for a high-end finish. It neatly defines the cushion’s shape, reinforces the seams, and provides a crisp, tailored edge. When you create piping from the same designer fabric, you get a cohesive, custom look you won't find in a big-box store.

A beautifully applied trim is like the perfect piece of jewelry for your furniture. It completes the look, adds personality, and signals an uncompromising attention to detail.

Troubleshooting for a Flawless Finish

Even pros run into hiccups. The key is knowing how to fix them. Here are a couple of common issues and how to solve them like an expert.

Problem: The Zipper Pulls or Puckers

A wavy zipper instantly cheapens the look. This usually happens when the fabric gets stretched unevenly during sewing.

- The Fix: Before sewing, press your fabric panels and zipper. Use plenty of pins or clips to hold everything flat and aligned. If you still get a pucker, carefully rip the seam, re-pin, and sew again slowly. It’s worth the extra ten minutes.

Problem: The Corners Aren’t Perfectly Crisp

Dull, rounded corners are a dead giveaway of a DIY project. You’re after sharp, 90-degree angles.

- The Fix: The secret is trimming the bulk. After sewing the corners but before turning the cover right-side out, snip the seam allowance diagonally across the corner. Be careful not to cut your stitches! This removes excess fabric, allowing the corner to pop out into a perfect, sharp point.

This focus on quality finishing is a massive trend, even in the outdoor cushion market. That market was valued at USD 5.6 billion in 2023 and is projected to hit USD 8.9 billion by 2032. With North America leading, it’s clear that homeowners from Cumming to Forsyth County are investing in premium, custom pieces for every part of their home. It underscores the demand for quality craftsmanship that looks exceptional while standing up to real life. You can learn more about the growing outdoor cushion market trends and see how this demand is expanding.

Your Custom Cushion Questions Answered

We get it. Kicking off a custom upholstery project brings up questions. After decades in our Buckhead showroom, we’ve heard them all from the sharpest homeowners and interior designers in Atlanta. Here are straightforward answers to the most common queries.

What Is the Best Fabric for Couch Cushions with Pets or Kids?

For a busy household, from Marietta to Milton, performance fabrics are your best friend. Don't even consider anything else. Look for industry leaders like Crypton or Sunbrella, both of which we carry extensively at our Atlanta fabric showroom.

Today's performance fabrics are engineered to resist stains, moisture, and fading while offering an incredible hand-feel. You no longer have to sacrifice a luxury look for practicality. Stop by our showroom on Piedmont Road and feel the difference.

Can I Make a New Cover for an Existing Cushion Insert?

Absolutely. This is one of the best ways to refresh a piece of luxury furniture Atlanta homeowners already cherish. The trick is to measure your existing insert with total precision.

A common mistake is making the new cover the exact same size as the insert. To get that snug, professional fit you see on a Wesley Hall sofa, your cover needs to be slightly smaller, usually by about half an inch on each side. This slight compression banishes saggy corners and gives you that perfect, plump look. Of course, if the old insert has seen better days, now is the time to replace it.

Should I Pre-Wash Upholstery Fabric Before Sewing?

This is a critical question. The answer is a firm: it depends on the fabric.

For most natural fibers, like cotton or the gorgeous Belgian linens we source, yes. These fabrics are prone to shrinking, and you want that to happen before you sew. On the other hand, many designer fabrics and performance textiles are treated with special finishes and should only be spot-cleaned.

Always check the manufacturer's care instructions. If you're ever in doubt, our design experts at Lewis and Sheron can give you specific guidance for any textile you choose from our collection of fine fabrics Alpharetta designers count on.

What Is the Difference Between a Knife-Edge and a Boxed Cushion?

Think of it as the difference between casual-cool and tailored sophistication.

- A knife-edge cushion is the simplest style. It's made from two pieces of fabric sewn together along a single seam, creating a sharp "knife" edge. It has a more relaxed, modern look.

- A boxed cushion is more structured. It features separate side panels (the "boxing") that give the cushion real depth and a clean, rectangular shape.

This is the style you'll find on almost all high-end furniture, from Lee Industries chairs to custom sectionals. It provides the clean, tailored appearance that is the hallmark of quality custom upholstery.

Ready to start your project with the finest materials Atlanta has to offer? Visit Lewis and Sheron Textiles in our Buckhead showroom or explore our collections online. Let us help you create something truly exceptional.